-

- Accidents and fatalities in confined spaces are disproportionately high given their prevalence in industries.

- Most accidents are preventable through effective and well-planned organizational preparedness.

- Hazardous gases are the leading cause of deaths in confined spaces; therefore, monitoring the air in confined spaces before entry and during work is essential.

Confined spaces are one of the most dangerous work environments in industries, resulting in more than 1000 fatalities in a decade in the USA. Although some improvement has occurred, the problem persists. The confined spaces account for 2% of occupational deaths and pose a disproportionate danger in the workplace. Understanding the immediate causes and conditions in the workplace that lead to accidents and fatalities can help employers mitigate the largely preventable risks associated with confined spaces in their facilities.

What is a Confined Space?

A confined space is only large enough to allow staff to enter and perform a limited number of specific tasks. The entryway is typically restricted, and the area often lacks ventilation. It is an area not meant for continuous occupancy.

Confined spaces occur in many industries. Personnel need to enter confined spaces to perform tasks, conduct inspections, perform maintenance and repairs, and engage in new construction, as well as for emergency rescue.

Examples of confined spaces include:

- Tunnels

- Tanks and vats

- Silos and storage bins

- Underground sewers, manholes, septic tanks, and storm drains

- Boiler and furnace

- Pipelines and pumping stations

- Trenches

- Shafts

- Dry or wet wells

The danger in these spaces arises from the processes and materials stored within, as well as the structure itself.

Some confined spaces are more dangerous than others, and in the USA, the Occupational Safety and Health Administration (OSHA) classifies them as “permit-required confined space” (PRCS). These are confined spaces that have one or more of the following characteristics:

- It can potentially contain a hazardous atmosphere, which can incapacitate people or cause injury or illness. The atmosphere is considered dangerous if it contains gases that are toxic, flammable, inert, or has an oxygen deficiency or excess.

- Stores materials that can engulf people

- Walls converge inwards

- Floors slope downwards

- Contains machinery, live wires, or exposure to heat stress

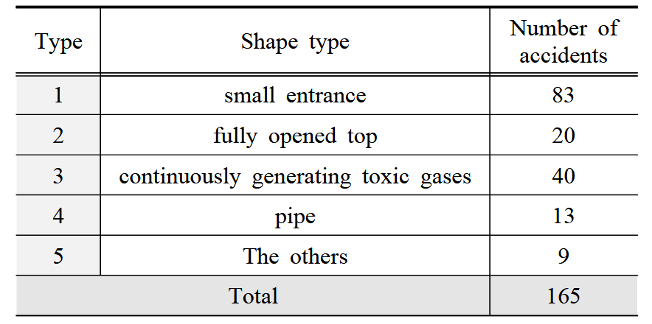

For example, a study in South Korea found that a small entrance, followed by hazardous gas generation, was the condition that caused the most accidents in confined spaces, see Table 1.

Table 1: Types of confined spaces, Lee et al. 2016. (Credits: https://doi.org/10.15269/JKSOEH.2016.26.4.436)

Non-permit confined spaces do not contain conditions or atmospheres hazardous to people.

An All-Pervading Problem

Confined spaces are a problem worldwide. The USA has reduced fatalities and accidents through regulations; however, in developing countries such as China, India, and Brazil, inadequate rules or their enforcement often cause more accidents. In India, confined spaces are responsible for 40% of industrial accidents, namely in the manual scavenging and informal manufacturing sectors.

Not enough studies have been conducted globally to identify the potential dangers associated with work sites, task-specific reasons, equipment failures, and other characteristics. Despite existing strict regulations, even in the USA, accidents in confined spaces persist.

From the studies conducted so far, several common causes have been identified; however, regional differences exist due to local work practices and regulations.

Causes of Accidents and Fatalities

Four types of occupational hazards in confined spaces are chemical/atmospheric, physical, ergonomic, and biological. In most countries, physical and chemical factors are the top two causes that lead to fatalities.

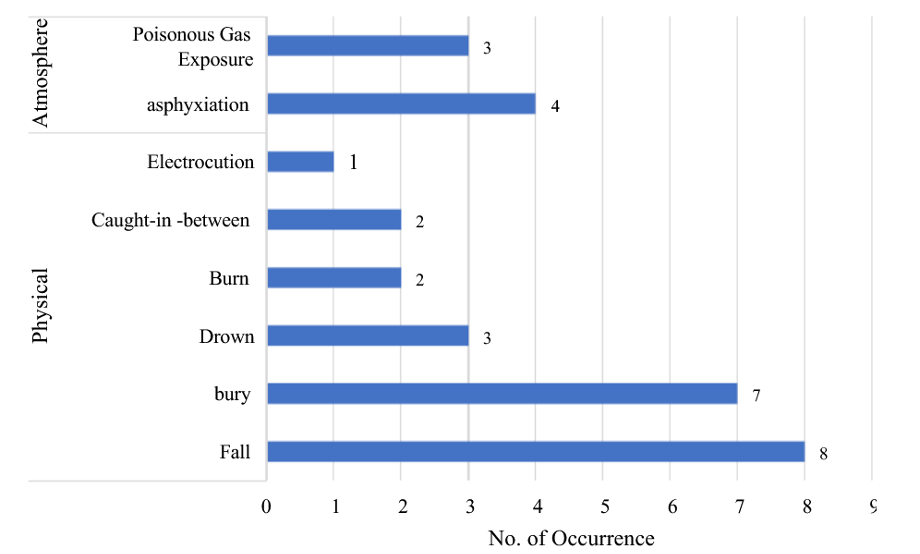

Figure 1: “Incident type based on hazard category in Malaysia,” Afrin et al. 2024. (Image credits: https://doi.org/10.1007/s43621-024-00197-3)

According to OSHA in the USA, 56% of confined space fatalities were caused by gases. Toxic gases, such as hydrogen sulfide and carbon monoxide, as well as oxygen deficiency, were the primary causes of accidents. Around 20% of fatalities were due to physical hazards from falling objects, structural collapses, and mechanical equipment. About 11% deaths were due to engulfment by soil, grains, or water.

In Malaysia, physical hazards such as falls, getting buried, drowning, burns, and electrocution caused 59% of fatalities between 2010 and 2021. Around 18% of deaths in confined spaces were due to hazardous atmospheres. Figure 1 shows the number of accidental deaths in each category.

The industry with the highest accidents and fatalities in confined spaces is construction in the USA and Malaysia, accounting for 61% and 53% of lost lives, respectively.

Unsafe Conditions and Acts Leading to Injuries and Fatalities

While physical and chemical hazards are the primary causes, immediate conditions and workplace acts also contribute to accidents in confined spaces.

The main conditions that cause accidents are as follows:

- Lack of or improper use of personal protective equipment /PPE.

- Lack of adequate training and knowledge of risks in confined spaces.

- Non-adherence to national rules before entering confined spaces

- Inadequate communication.

These conditions are commonly found worldwide, but their role in causing accidents can vary.

Existence of Hazardous Gases

Many processes and materials present in confined spaces can generate toxic gases. The methods include plant decomposition and material processing, human respiration, chemical reactions, work processes, and equipment operation. Often, gases generated in neighboring areas can seep into confined spaces and accumulate.

The gases that can form are hydrogen sulfide, carbon monoxide, oxygen deficiency, ammonia, chlorine, nitrogen dioxide, hydrogen cyanide, methane, VOCs, and propane. For example, Hydrogen sulfide is produced in sewers, and with little ventilation underground, it accumulates to levels that are poisonous or flammable. Grains respire in grain silos to create oxygen-deficient conditions. The accidental release of propane can deplete oxygen in other confined spaces.

In Malaysia, the presence of hazardous gases was identified as the most prominent unsafe condition in confined spaces, as shown in Figure 1.

Lack of Proper PPE Use

Failure to use PPE, improper use of PPE, or the use of inappropriate PPE accounted for 85% of accidents in Malaysia, resulting in both physical and chemical risks. Though OSHA has provided strict guidelines, the lack of appropriate PPE caused 35% of fatalities in the USA. A study in Malaysia revealed that employers lack awareness of the dangers associated with confined spaces, placing workers at risk due to inadequate PPE in workplaces.

Inadequate Organization

Inadequacy in organization encompasses a lack of training, inadequate supervision of work in confined spaces, and faulty equipment and devices.

Training: A lack of proper training for personnel in confined spaces, including their dangers, risks, and emergency actions, is a globally prevalent problem that employers must address. In the USA, only 30% of employees receive annual training on confined space entry.

Faulty equipment: The air monitoring and warning equipment and devices may be operated at sub-optimal conditions. Process equipment, pipes, and connections can wear and develop weak points where leaks or accidental gas releases can occur. Uncalibrated gas monitors cannot provide accurate readings and may miss dangerous gas accumulation.

Missing safety protocols: Many facilities lack emergency safety procedures and evacuation plans.

Inadequate communications

Personnel often hesitate to report workplace problems for fear of retaliation, which can delay repairs and jeopardize workers’ safety; in the USA, 68% of workers wouldn’t be prepared to report unsafe conditions. Workers entering confined spaces often fail to promptly warn colleagues of the dangers they face. This can happen due to the unavailability of communication devices and systems. It also occurs when subcontracted teams are involved and various teams fail to communicate effectively. Employers may not provide subcontractors with sufficient information, drawings, and plans for the work.

Hence, unsafe conditions arise from the nature of activities or from employers’ inadequate attention to industrial hygiene, while employees engage in dangerous acts due to insufficient support systems.

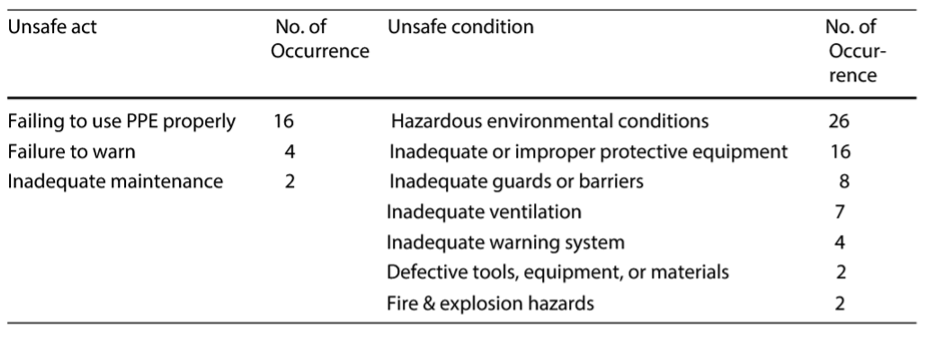

Table 2: “Statistics of unsafe acts and unsafe conditions based on SCAT,” Afrin et al. 2024. (Image credits: https://doi.org/10.1007/s43621-024-00197-3)

Preventing Confined Space Accidents

Most confined-space accidents are preventable. The leading cause of confined space accidents is failure at the management level; they must make the most significant changes to prevent them. However, personnel must also be involved and prioritize safety by following instructions, as they are the ones who enter the confined spaces and risk their safety, lives, and health.

The following are some standard measures that employers can adopt to make their confined spaces safer for workers.

Training

OSHA has concluded that regular annual training for personnel on the working conditions and hazardous gases present in confined spaces, along with mitigation strategies, is necessary and can prevent 85% of accidents. Regular training provides an opportunity to incorporate new information on risks and remedial measures, and serves as a refresher for staff.

The staff must be trained on all PRCS requirements, including hazard identification, air monitoring, and the importance of communication during each confined-space visit. OSHA estimates that enforcing and following PRCS can reduce incidents by 42%. Both employers and employees must be involved.

Only personnel trained in confined spaces should enter for work.

Risk assessment

Safety managers and industrial hygienists must assess risks associated with their confined spaces. The processes, atmosphere, equipment, structure, and conditions will vary depending on the type of confined space and the associated industrial activity. Hence, identifying the gases and potential generation rates can help determine the engineering and administrative controls, as well as the choice of PPE. In France, many industries have never conducted a risk assessment for confined spaces. Regular assessments and evaluations help to maintain safety.

Work protocols, instructions, and supervision

Employers must provide well-defined work plans and procedures for working in confined spaces and communicate them to the personnel.

- Only workers with a permit must enter confined spaces. A competent person must be appointed to issue permits for entry into confined spaces.

- A list of hazardous equipment, marking work zones, estimating the time required for the work, and the PPE to be used are some basic information that should be included in the work plans.

- The work protocols must cover emergency procedures, including evacuation plans in the event of an incident or accident, and ensure necessary resources are readily available.

- The protocols must be documented and given to employees.

- Place visual reminders to ensure the use of PPE, gas monitors, and other necessary equipment, to maintain heightened awareness of dangers in confined spaces.

- Trained supervisors must be assigned to oversee work in confined spaces and maintain communication with staff during operations in these areas. Supervisors must ensure that all workers are using PPE, as some may not prioritize its use.

- Provide whistleblower protection to encourage workers to report unsafe working conditions.

Provide Proper PPE

It is the employer’s responsibility to keep their staff safe and healthy by preventing occupational hazards. Industrial hygienists and safety managers must choose the appropriate PPE for the work that staff must carry out in confined spaces. Respiratory, harnesses, and fall protectors may be necessary. Staff working in confined spaces must also be given functional communication devices.

Monitor the Air

Monitoring the air in confined spaces is mandatory for PRCs. However, it is good practice to adopt before entering any confined space where gas-generating processes are present. Corrective actions are required before entry if toxic gas concentrations exceed permitted limits, flammable gases exceed 10% above their lower flammable limit, oxygen deficiency (less than 19.5%), or excess oxygen (over 23.5%) are detected.

Gas detection must be maintained even during the brief periods when people work in confined spaces.

The gas detectors must be regularly inspected, calibrated, and bump-tested to ensure accuracy.

Engineering controls

Maintain and use equipment for purging confined spaces of hazardous gases when their levels exceed safe limits. The purging method must be suitable for removing the gas. The dangerous gases must be removed to reach normal levels before workers enter the confined spaces.

Install ventilation systems to remove hazardous gases and introduce clean air.

All equipment, devices, and PPE must be regularly inspected, checked, and repaired to ensure they are functional and do not pose any risk to employees. Damaged equipment and PPE should be replaced if they cannot be repaired.

Eliminating confined space work

Employers can consider incorporating drones into operations in confined spaces, where possible, to reduce the need for personnel to enter. Robotic sensors can be deployed to test the air before entry. Drones and robotics are expected to reduce fatalities in the USA by 30% in the future.

Preventing Accidents in PRCS

In countries like the USA, national agencies such as OSHA provide rules that employers must follow when working in confined spaces. As part of regulation 29 CFR 1910.146, OSHA requires the following precautions before entering confined spaces:

- Staff have received training and obtained their employers’ permits to enter PRCS.

- Identify the presence of any physical or atmospheric hazards.

- Always maintain communication with a person outside confined spaces.

- Use PPE, ventilation, and air monitoring devices during work in confined spaces.

- Only trained personnel should attempt rescue operations in confined spaces.

Choose Reliable Gas Detectors

Testing the air before and during operations in confined spaces is crucial for ensuring the safety and well-being of workers. It is therefore necessary to select reliable, accurate devices capable of measuring subtle changes in gas concentrations in real time. Interscan produces the GasD 8000 Portable Gas Monitor, equipped with sensors for over 20 gases, including common hazards in confined spaces, and capable of continuous operation for 8 hours. It features visual and audio alarms to alert workers to changes in gas levels, as the sensors can measure gas concentrations in parts per million (ppm) or parts per billion (ppb). It has data logging and can be integrated with safety systems and data acquisition systems.

Book a consultation to learn more about the Interscan GasD® 8000 Portable Gas Monitor and our support services.

FAQ

1. Why are confined spaces so dangerous in the workplace?

Confined spaces are dangerous because they often have limited ventilation, restricted entry and exit, and can accumulate toxic gases like hydrogen sulfide and carbon monoxide. These conditions lead to oxygen deficiency, explosions, or poisoning, making them one of the most hazardous work environments.

2. How can confined space accidents be prevented?

Most accidents can be prevented through proper training, risk assessment, and air monitoring. Employers must enforce OSHA’s permit-required confined space (PRCS) rules, ensure all personnel use appropriate PPE, maintain equipment, and continuously monitor the air before and during entry.

3. What is the most common cause of fatalities in confined spaces?

Hazardous gases are the leading cause of confined space deaths, accounting for over half of such deaths. Regular air testing, ventilation, and use of reliable gas detection equipment, like portable monitors calibrated for multiple gases—are essential for preventing such fatalities.

Sources

Arifin, K., Ahmad, M.A., Abas, A. et al. (2024). Identification of root cause of fatal confined space incidents in Malaysia and strategies for prevention. Discov Sustain 5, 36. https://doi.org/10.1007/s43621-024-00197-3

New York FACE Program. (n.d). Module 2: confined space awareness: Preventing deaths and injuries to workers. Retrieved from https://www.health.ny.gov/environmental/investigations/face/training/docs/confined_space_awareness_training.pdf

French Ministry For Sustainable Development. (n.d.). Accidents in Confined Spaces. Retrieved from https://www.aria.developpement-durable.gouv.fr/wp-content/files_mf/ACCIDENTSCONFINED_SPACES.pdf

OSHA Online Center: (2024, Dec 9). Statistics Show The Danger of Confined Spaces. Retrieved from https://blog.oshaonlinecenter.com/confined-space-hazards-statistics/