- Hazardous Gases on farms, which can be poisonous or flammable, are produced in sealed silos, anaerobic digesters, and manure storage.

- The hazards that must be controlled are hydrogen sulfide, ammonia, methane, nitrogen oxides, carbon monoxide, and carbon dioxide.

- Before entering confined and sealed areas, the air inside should be checked for manure gases, using portable gas detectors with long detection tubes.

- Proper ventilation is always necessary in animal stalls and manure areas, as well as before and during visits to silos, to avert most harm.

Agriculture has one of the highest rates of occupational health hazards. Occupational hazards were first recognized in 1555 due to the respiratory problems of farm workers. However, nowadays, occupational health problems in this industry do not receive the same level of attention as those in heavy industries. In this article, you can find out the most common hazardous gases that are one of the main groups of occupational hazards workers have to deal with on farms.

Occupational Hazards on a Farm

Many occupational safety and health (OSH) hazards exist in agriculture, including extreme weather, extensive use of chemicals, exposure to animals and plants, prolonged working hours, physical labor, and hazardous machinery and equipment.

According to the International Labour Organisation (ILO), approximately half of the global labor force, which is around 1.3 billion people, works in the agricultural industry. Agricultural workers are at a high risk of occupational hazards for several reasons, which increase the incidence of injuries and health problems. Some of the reasons outlined by the ILO are listed below:

- Workers often have limited skill sets and training in recognizing hazards and understanding occupational safety and health issues.

- A significant proportion are temporary, casual, and waged workers with no entitlement to protection.

- The working conditions are hazardous, especially in small-scale farms, with no access to adequate personal protective equipment (PPE).

- In many countries, there is no national legislation or regular inspections protecting workers from OSH problems.

Poor work conditions lead to environmental risks, which can spill over into home situations. For example, when workers do not wash away harmful chemicals before going home, it can transfer to and harm more susceptible children.

Chemical Hazards

The chemicals that can be hazardous due to inhalation include pesticides, agrochemicals, and a few dangerous gases that may be formed or present in various situations on the farm.

- Agrochemicals can be inhaled as aerosols, fine liquid spray, or pesticide fumes. Other concerns include dust and smoke.

- Some chemicals that are gases can also be poisonous and hazardous.

Hazardous gases on farms

Hazardous gases found on farms are mainly formed as a result of farming processes.

These gases are commonly found in confined spaces, such as manure storage facilities, silos, grain bins, anaerobic digesters, and poorly ventilated barns. Silo fermentation utilizes available oxygen and, like anaerobic processes, produces manure gases that accumulate in confined spaces in concentrations that are harmful to people entering them. The gases can last in the confined spaces up to two weeks.

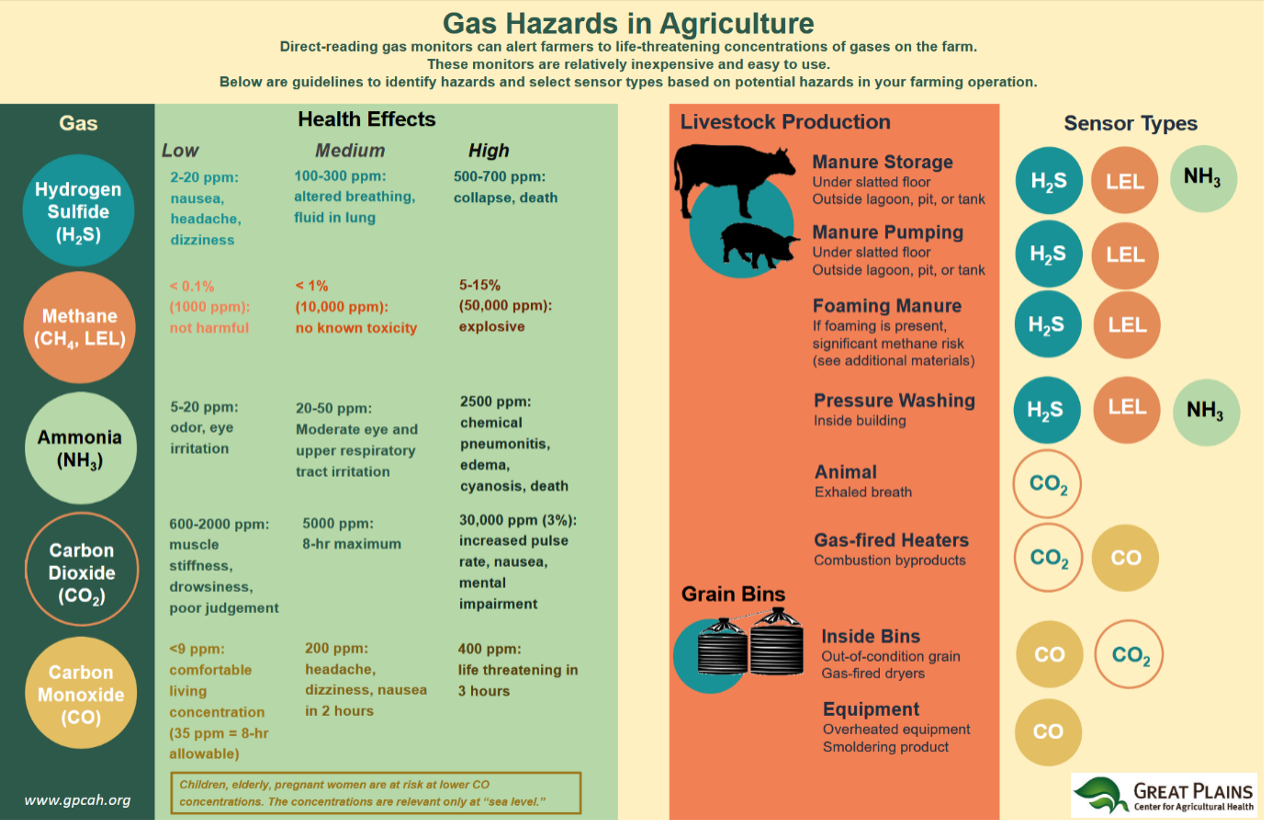

The common hazardous gases on farms include methane, ammonia, hydrogen sulfide, carbon dioxide, carbon monoxide, nitrogen dioxide, and nitric oxide, as shown in Figure 1.

Figure 1: Gas Hazards in Agriculture. The figure shows guidelines to identify hazards and select sensor types based on potential dangers in your farming operations,” OSU. (Image credits: https://cfaessafety.osu.edu/sites/safety/files/imce/Gas-Hazards_2017.pdf)

Methane

Methane (CH4) is produced through the anaerobic breakdown of organic material. It is the process used in biogas production to generate methane, which is stored and utilized as a fuel. It is a colorless, odorless gas lighter than air and accumulates in headspace and unventilated spaces. It can also be produced from manure, which in the open does not cause any problems, as the gas can disperse. However, solid and liquid manure stored in closed barns, when agitated, release methane, which can accumulate in quantities sufficient to cause fires and explosions that can result in injury or death to workers. Faulty plumbing lines can also lead to the accumulation of methane.

Several incidents of fires caused by methane gas in hog barns demonstrate that methane poses a significant safety risk to workers, livestock, and property. When the air has more than 50% methane, it can asphyxiate people.

“The American Society of Agricultural and Biological Engineers” has provided guidelines for the management of manure storage and ventilation to reduce risks of fires, explosions, asphyxiation, and poisoning from manure gases.

Ammonia

Ammonia (NH3) is another gas produced from manure. The nitrogen compounds in animal manure decompose to generate ammonia. The gas is found in buildings housing poultry, rabbits, and pigs, as well as in areas where manure is composted.

The gas is colorless with a characteristic odor and is lighter than air. It can accumulate in stalls, and chronic exposure to ammonia can lead to respiratory problems in livestock. Early detectable symptoms of ammonia accumulation include eye irritation in humans and animals, which occurs at concentrations of 20–50 ppm. Ventilating the buildings is advised in these cases. Small family-run poultry farms are also at risk, as people entering the buildings may not be using respiratory protection.

Hydrogen sulfide

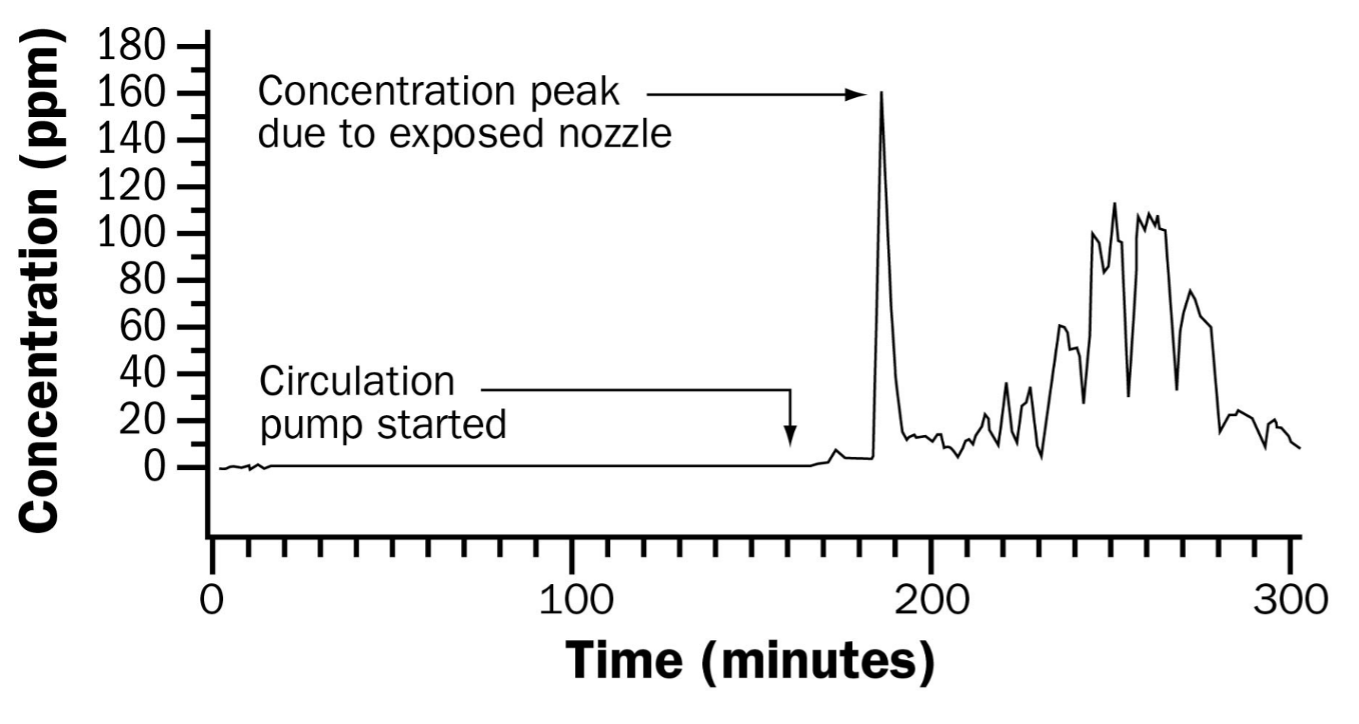

Hydrogen sulfide (H2S) is toxic and a safety hazard, and should be considered the most dangerous manure gas. H2S levels are usually low, especially during cooler temperatures, when the manure is undisturbed. However, when the manure is agitated on the surface, H2S levels can rise rapidly to dangerous levels, as shown in Figure 2. Underground manure storage units can be particularly hazardous. Manure that undergoes anaerobic decomposition develops manure gas, including H2S, which can reach high levels during warm weather and poor ventilation.

Liquid manure and anaerobic digester tanks can have little or no oxygen and significant concentrations of the gas. Biogas facilities are also at risk of accumulating this gas. Deaths among farm workers entering manure storage or rooms above storage areas have been reported. Small amounts of the gas can also exist in small poultry or animal stalls.

Figure 2: “H2S gas concentration during pit agitation,” Ontario.ca. (Image credits: https://www.ontario.ca/page/hazardous-gases-agricultural-operations)

The gas smells like rotten eggs at lower concentrations, but at 100 ppm, it causes paralysis of the sense of smell and can lead to instant death. Respirators are needed at 10 ppm and above before entering areas with H2S.

H2S is a fire hazard. The gas is heavier than air and can travel a distance to cause fires and explosions.

Read this resource to find out more about H2S and its control.

Carbon Monoxide

Carbon monoxide (CO) is produced from appliances or vehicles in confined spaces or rooms with poor ventilation. It is produced due to the incomplete combustion of fossil fuels, wood, and charcoal. With proper maintenance of equipment and rooms, the danger from this gas can be minimized.

CO is also used as a rodenticide on farms and can cause accidental poisoning if PPE does not protect the personnel spraying.

CO is a colorless and odorless gas that is a chemical asphyxiant that reacts with blood’s hemoglobin and prevents oxygen transport, leading to death at high concentrations.

Carbon Dioxide

These areas have little or no oxygen and high levels of CO2, which can lead to asphyxiation. Sealed silos should not be entered without proper respiratory protection and oxygen support systems in place. Livestock buildings with adequate ventilation will not have CO2 accumulation.

Nitrogen Dioxide and Nitric Oxide

Nitrogen dioxide (NO2) and nitric oxide (NO) are produced in silos immediately after plant materials are stored. Usually, NO2 measurements are made because it is five times as poisonous as NO. The amount of the gases produced depends on weather conditions and cultural practices, which influence the amount of nitrates that crops will contain. Corn crops absorb more nitrates from the soil during rainfall after a dry growing period, just before harvest. The plants have a high nitrate content that leads to the formation of NO and NO2. Nitric oxide is unstable and combines with oxygen to form NO2.

Exposure to NO2 and NO is called silo filler diseases. NO2 is reddish-brown with a bleach-like odor. Even short-term exposure can cause death, since the gas forms nitric acid in the lungs and burns the tissue. Lower concentrations cause chronic respiratory problems. The gas is heavier than air and escapes into silo chutes and enters feed rooms.

Silo ventilation should be operated for 30 minutes before entering and while people are inside to maintain low levels of silo gases.

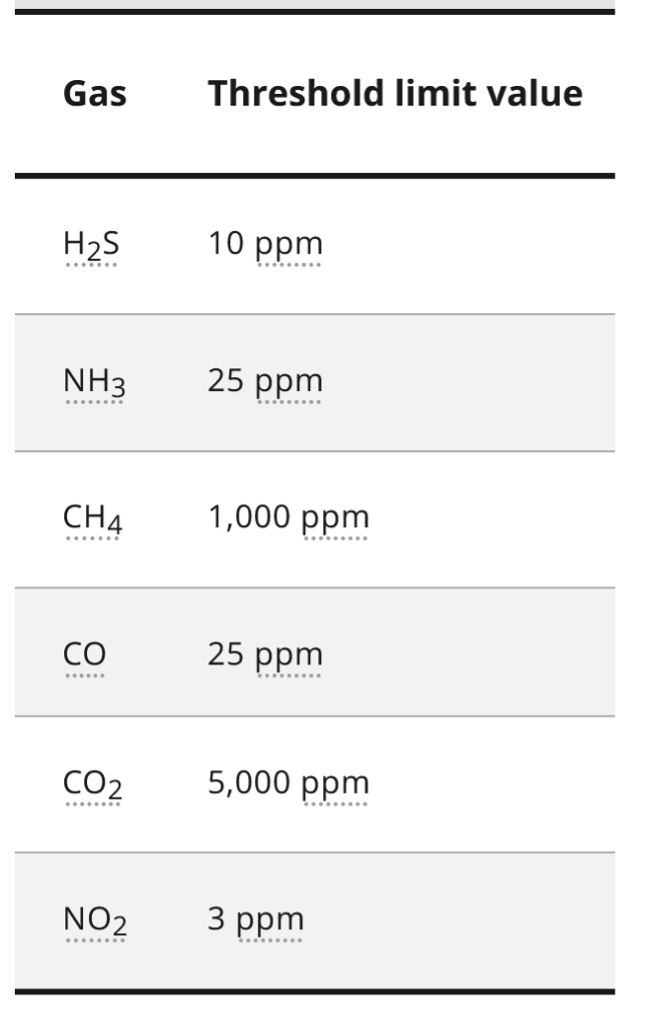

Table 1. “Threshold limit values (time weighted average) for maximum gas concentrations in humans, ASABE EP470.1 Standard, OCT2011 (R2016)” Ontario.ca. (Credits: https://www.ontario.ca/page/hazardous-gases-agricultural-operations)

Maintain Safe Gas Levels

The American Conference of Governmental Industrial Hygienists has recommended safe levels of the gases in workplaces, as shown in Table 1. These levels of the gases should be maintained in silos, biogas digesters, and manure storage facilities, to ensure that farm workers are not affected. People should not enter these areas without first checking the gas levels. To prevent harm while entering confined spaces, the person conducting the air tests should use appropriate respiratory protection, complete with a breathing apparatus. Portable gas analyzers connected to gas detection tubes can also be used to prevent entry into these areas for checking gas levels.

Interscan provides the GASD 8000 Portable Gas Detector, which can have individual sensors for ammonia, carbon dioxide, carbon monoxide, hydrogen sulfide, nitric oxide, and nitrogen dioxide. Gas detection, appropriate PPE, and engineering controls like ventilation can keep the gases under control and people safe and healthy.

Contact Interscan to learn more about our portable gas analyzers for your farm operations.

Sources

Cole, D. (2006). Understanding the links between agriculture and health for food, agriculture, and the environment. Retrieved from https://lib.icimod.org/records/30k03-0zc80

ILO. Org. (n.d.). Chemical hazards in the agricultural sector. Retrieved from https://www.ilo.org/sites/default/files/wcmsp5/groups/public/@ed_protect/@protrav/@safework/do cuments/instructionalmaterial/wcms_871784.pdf

Kearney, G. D., Shaw, R., Prentice, M., & Tutor-Marcom, R. (2014). Evaluation of respiratory symptoms and respiratory protection behavior among poultry workers in small farming operations. Journal of agromedicine, 19(2), 162–170.

https://doi.org/10.1080/1059924X.2014.886536

Ontario.ca. (2023, Jan 9). Hazardous gases in agricultural operations. Retrieved from https://www.ontario.ca/page/hazardous-gases-agricultural-operations

Respiratory health hazards in agriculture. (1998). American journal of respiratory and critical care medicine, 158(5 Pt 2), S1–S76.

https://doi.org/10.1164/ajrccm.158.supplement_1.rccm1585s1