In the realm of industrial safety, the detection and monitoring of hazardous gases are pivotal. Electrochemical sensors stand out as a sophisticated technology designed for this purpose, providing reliable and accurate measurements critical for maintaining safe working environments.

This article will delve into the benefits of electrochemical sensors in gas detection, their importance in industrial settings, and provide actionable insights for safety managers, industrial hygienists, and other professionals concerned with industrial hygiene and safety.

Understanding Electrochemical Sensors

Electrochemical sensors operate by measuring the electrical currents generated by the chemical reaction of the target gas on an electrode, which directly correlates to the concentration of the gas present.

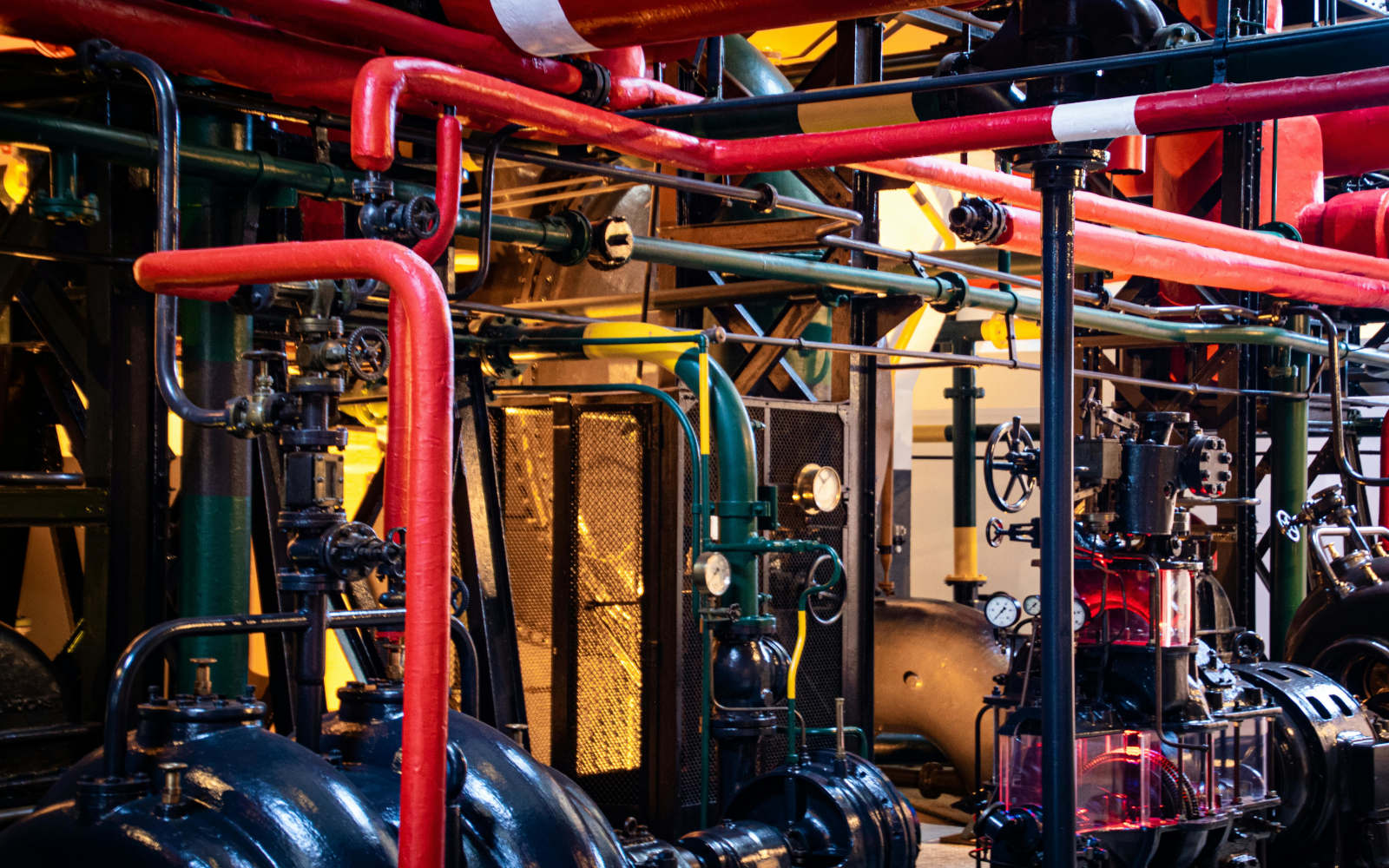

This technology is renowned for its specificity, sensitivity, and rapid response times, making it ideal for continuous monitoring of environments like manufacturing plants, laboratories, and other industrial areas.

Advantages of Electrochemical Sensors in Gas Detection

1. High Sensitivity and Accuracy

Electrochemical sensors can detect trace levels of gases, often down to parts per million or even parts per billion. This high sensitivity is crucial in industrial settings where early detection of hazardous gases can prevent health risks and enhance workplace safety.

2. Longevity and Reliability

These sensors are built to last with minimal maintenance. Their long operational life and stability ensure continuous protection without frequent recalibration, making them a cost-effective solution for ongoing gas monitoring.

3. Wide Range of Detectable Gases

Electrochemical sensors are versatile, capable of detecting a broad spectrum of gases including toxic and combustible gases like carbon monoxide, hydrogen sulfide, and ammonia. This makes them an indispensable tool in a variety of industrial applications.

4. Environmental Resistance

These sensors perform well under different environmental conditions, including variations in temperature and humidity. This robustness is essential for reliable gas detection in harsh industrial environments.

5. Real-Time Monitoring

The ability to provide real-time, continuous monitoring allows for the immediate detection of gas leaks, facilitating swift responses that can mitigate potential hazards and operational disruptions.

Case Studies and Real-World Applications

Incorporating case studies, such as the implementation of these sensors in a chemical manufacturing plant, illustrates their effectiveness. For example, a facility may use these sensors to continuously monitor the air for toxic byproducts.

Upon detection of a harmful concentration of gases, automated systems can initiate ventilation or shut down operations, significantly reducing the risk of exposure and maintaining compliance with safety regulations.

Integrating Electrochemical Sensors into Safety Protocols

Safety managers and industrial hygienists can integrate electrochemical sensors into their safety protocols by:

- Establishing regular maintenance schedules to ensure sensor accuracy.

- Training personnel on the interpretation of sensor readings and appropriate response strategies.

- Using data logged from the sensors for trend analysis and predictive maintenance.

Electrochemical sensors are a cornerstone of modern industrial safety systems, providing essential protection against gas-related hazards. Their accuracy, reliability, and versatility make them a preferred choice for gas detection in diverse industrial settings.

To enhance the safety of your facility with state-of-the-art gas detection technology, consider the reliable solutions offered by Interscan. Our range of electrochemical sensors, including the Accusafe and GasD 8000 systems, are designed to meet your specific needs. Contact us today to request a quote and learn more about how our products can support your safety initiatives.