- The textile industry is vast and uses many chemicals, many of which are occupational hazards.

- Some of the gases are fire hazards, but all are health hazards.

- Emissions highlight the need for enforcing stringent monitoring, safety measures, proper ventilation, and regulations to mitigate chemical exposure risks in the textile industry.

Gas detection is a necessary precaution for the textile industry. The occupational safety and health concerns of workers in the textile manufacturing sector are becoming severe due to the risk of chronic effects that can be long-lasting. Various chemicals are used to make different fabrics in multiple processes, and the textile industry is the second most significant source of pollution. Read the article to learn more.

The Textile Industry

The vast textile industry covers several processes for changing fibers into a fabric or completed garment. These processes include spinning yarns from raw materials, weaving the yarns into different fabrics, dyeing, finishing, strengthening, etc.

Moreover, there is a vast range of fibers that exist:

- Natural textiles like cotton, silk, wool, jute, rayon, lycel, etc.

- Synthetic fibers such as acrylic, nylon, and polyester

The processes and chemicals used will differ with each fabric type, so the textile industry uses a wide range of chemicals collectively. Many of these chemicals are harmful to people’s health and the environment.

Pollution in the Textile Industry

The textile industry is the second most polluting industry in the world, responsible for 8% of global carbon emissions and 20% of global wastewater. Since per capita consumption of textiles tripled between 1950 and 2008 and is still increasing, pollution from the industry is a matter of concern.

Water, air, noise, and vibration pollution are the primary challenges in the textile industry.

Air pollution is the change in gas composition or increase in particulate matter due to the industry. The common forms of air pollution in the textile industry are exposure to the following forms of pollutants:

- Dangerous chemicals and dyes give out toxic emissions, vapors, fumes, and gases

- Dust from fabrics and machines from weaving and fabric manufacturing causes dust and adds particulate matter.

- Excessive cotton dust is also prevalent in spinning and processing units. Workers can be exposed to high concentrations of cotton dust, soil, and pesticides used in cotton.

Gaseous emissions occur through two means- stack and non-point.

- Stack emissions: Manufacturing generators and boilers produce polluted air through stacks. Steam from water and coal produces carbon monoxide, sulfur oxides, and carbon dioxide, which are environmental hazards.

- Non-point emissions: However, several processes produce fugitive or non-point emissions that can create occupational hazards for workers. Non-point emissions are eventually vented outside.

Processes Causing Emissions

Significant chemical exposure risks in the textile industry are specific to processes and units.

- Wet processes: Steps like stenting, printing, curing, drying, and dyeing create small emissions. However, due to their toxic nature, they can be hazardous and should be prevented. These can be carbon dioxide, nitrogen oxides (NOx), sulfur oxides (SOx), VOCs (volatile organic compounds), etc.

- Instant cleaners: Several instant cleaning agents, like chlorofluorocarbon (CFC) and carbon tetrachloride (CTC), are ozone-depleting compounds that need to be phased out.

- Finishing: Several finishing processes, such as singeing, calendaring, and drying, use liquefied petroleum gas (LPG), which increases hazards, poses risks to workers’ health and safety, and causes environmental pollution.

- Tanning: Textile tanning uses tannic acid/tannin as a mordanting process during dyeing for natural fibers like silk. Hydrogen sulfide (H2S) is released during chrome tanning processes, where it can be released during decalcifying and maceration steps. Concentrations can be permitted four times, so decalcifying and maceration units must be strictly monitored.

- Combustion: Methane (CH4) is used as a fuel for several processes, and leaks can produce explosive mixtures.

- Drying and curing: Drying and curing at high temperatures release several toxic hydrocarbons: formaldehyde and acetic acid fumes. These two chemicals are harmful to people, animals, and the environment.

- Various textile stages: Processes such as printing, dyeing, fabric preparation, and wastewater treatment contribute to air pollution. Emissions include hydrocarbons, formaldehyde, acids, and other toxic gases.

Health Hazards

The US Occupational Safety and Health Administration (OSHA) has categorized hazards in the textile industry into physical, ergonomic, psychological, biological, and chemical hazards.

The gas emissions are chemical hazards. Some, like H2S and methane, are fire risks, but all have health consequences.

Health problems

Lung disease is the foremost occupational hazard faced by textile industry workers. Other health problems include reproductive system disorders, neurotoxicity, and dermatological conditions.

- Lung diseases caused by all three forms of air pollution found in the textile units can be byssinosis, diffuse lung disease, dry cough, discomfort in breathing, chest constriction, and chronic bronchitis. Byssinosis due to cotton dust can be lethal. Asthma occurs due to hypersensitivity to chemicals used in the industry.

- Dermatitis is due to the presence of toxic chemicals like formaldehyde.

- Loss of consciousness occurs due to various toxic fumes

- Eye problems include diminishing visibility, permanent damage, and the persistence of fog, which are also reported.

- Liver diseases are common among workers in the dyeing units.

Many of the symptoms do not present themselves immediately but can occur for weeks and months due to low-level but chronic exposure to problematic chemicals.

Non-chemical hazards can also cause mental stress and noise-induced complications.

Regulatory Standards

Given the high number of probable causes for occupational hazards in the textile industry, OSHA has implemented mandatory regulations that the textile units must follow, especially in the cotton sector.

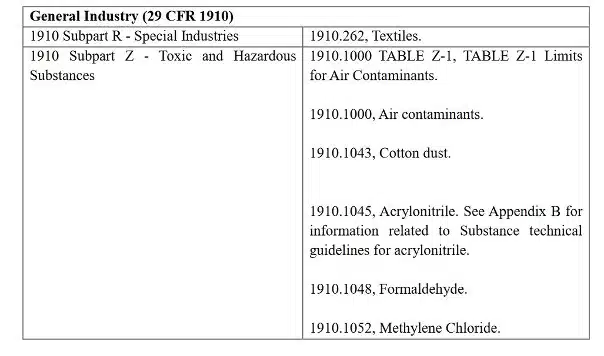

OSHA has issued guidelines for textiles (1910.262) under the general industry section (see Table 1). The guidelines are comprehensive and cover all aspects of production, including design, processes, installation, operation, and maintenance of facilities, equipment, and machinery for all textiles. They also include standards for occupational safety and health.

Table 1.: OSHA textile-related standards, Mekala et al. 2023. (Image credits: Res. Technol. Eng. 4 (4), 2023, 127-140)

For example, the maximum permissible levels over an eight-hour shift for cotton dust are as follows:

- 200 micrograms of cotton/cubic meter of air in yarn manufacturing units

- 500 micrograms/ cubic meter of air in material waste houses

- 750 micrograms/ cubic meter of air in weaving units

- 1000 micrograms/ cubic meter of air in waste recycling facilities

For more details, consult OSHA online resources.

Mitigating Hazards in the Textile Industry

The specific hazard will depend on the fabric being produced and the various stages of the processes. Therefore, though the specific preventive and remedial actions will differ, the method remains the same and is as follows:

- Identify and assess risk level.

- Evaluate risk by constant monitoring with fixed and portable gas detectors.

- Choose the preventive measures. For example, personal protective equipment can reduce respiratory problems.

- Implement preventive measures, such as engineering controls to reduce emissions. The control technologies for gaseous emissions and particulate matter will be different, like filtering for sulfur.

- Monitor safety through regular inspections of the facilities.

Monitoring and Gas Detection in the Textile Industry

Accurate gas detectors that give results rapidly are necessary for constant monitoring and spot checks. Interscan offers devices for both purposes.

- Interscan’s Accusafe can constantly monitor at one or more points, with data logging possibilities on a central device.

- Interscan’s GasD® 8000 portable gas analyzers can be carried for spot checks where no fixed sensors exist.

Both devices can be fitted with sensors for several gases of choice and have audio and visual alarms. Preventive measures like monitoring reduce risks and increase employee confidence in their workplace, supporting more production.

Vijayalaxmi Kinhal

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

Akhtarujjaman, M. (2022, Sept, 27). Concepts and technologies for air emission control in the textile & apparel industry. Retrieved from https://www.textiletoday.com.bd/concepts-technologies-air-emission-control-textile-apparel-industry.

Alanezi. A.M. (2018). Impact of pollution generated by the textile Industry on health and environment. Journal of University Studies for Inclusive Research, 2 (3), 160-176.

USRIJ. Retrieved from https://usrij.com/wp-content/uploads/2020/01/IMPACT-OF-POLLUTION-GENERATED-BY-THE-TEXTILE-INDUSTRY-ON-HEALTH-AND-ENVIRONMENT.pdf

Ammayappan, L., & Moses, J. (2007). An overview on application of tanning in textile processing. Retrieved from https://www.researchgate.net/publication/289977267_An_overview_on_application_of_tanning_in_textile_processing

Bailey, K., Basu, A., Sharma, S. (2022). The Environmental Impacts of Fast Fashion on Water Quality: A Systematic Review. Water 14, 1073. https://doi.org/10.3390/w14071073

Kumar, D.P, & Muthukumar. K. (2018). Industrial Health Hazards in Textile Industry. Journal of Automation and Automobile Engineering 3(3), 5-9. Retrieved from https://core.ac.uk/download/pdf/230497721.pdf

Mia R, Selim M, Shamim AM, et al. (2019). Review on various types of pollution problem in textile dyeing & printing industries of Bangladesh and recommendation for mitigation. J Textile Eng Fashion Technol. 5(4):220-226. DOI: 10.15406/jteft.2019.05.00205

Mekala, K. G. H., Malki, A. R. I., Amarasinghe, D. P. N. T., & Ishara, G. K. K. (2023). Occupational Health and Safety in the textile industry. J. Res. Technol. Eng. 4 (4), 2023, 127-140. Retrieved from https://www.jrte.org/wp-content/uploads/2023/10/Occupational-Health-and-Safety-in-the-textile-industry.pdf

Textile industry to phase out ozone depleting chemicals. (2005, Feb, 14). Retrieved from http://www.ctc-phaseout.org/