Gas detection and analysis are essential in many industries, including oil and gas, chemical, mining, and environmental monitoring. The capacity to swiftly and reliably identify and analyze gases contributes to maintaining a safe working environment, preventing accidents, and minimizing environmental damage. 2023 brought technical improvements that have considerably impacted gas detection and analysis, leading to new sensors, methods, and tools to meet the expanding demand for better safety and monitoring.

Gas Detection Technologies

1. Electrochemical Sensors

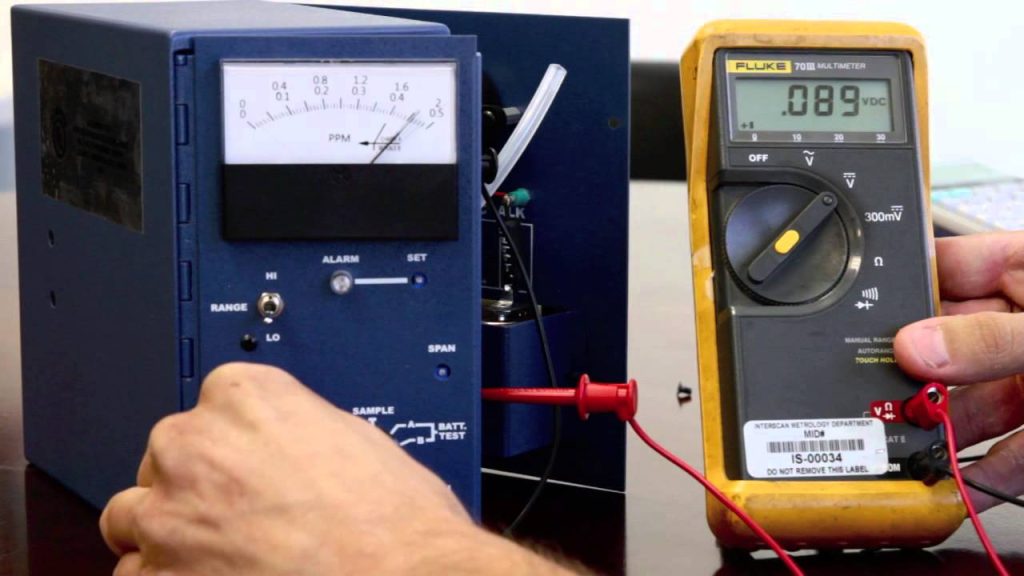

Toxic and combustible gas detection frequently uses electrochemical sensors. They work by detecting the electric current produced when a target gas reacts chemically with an electrode. Increased sensitivity and selectivity in electrochemical sensor technology over the past few years have made detecting trace quantities of gases in complicated settings possible.

2. Infrared (IR) Sensors

Infrared sensors detect gases by measuring gas molecules’ absorption of IR radiation. These sensors are beneficial for detecting combustible gases and carbon dioxide. Advancements in IR sensor technology have improved accuracy, response time, and stability and developed miniature, low-power sensors suitable for portable and remote monitoring applications.

3. Photoionization Detectors (PID)

Photoionization detectors ionize gas molecules using high-energy ultraviolet (UV) light, producing an electric current proportional to the gas concentration. As a result, PIDs are excellent for locating dangerous gases and volatile organic compounds (VOCs). In addition, PID technology has advanced primarily in downsizing and efficiency, enabling the integration of these sensors into small, portable devices.

4. Emerging Technologies

Among the other cutting-edge detection techniques gaining popularity recently are sensors based on nanotechnology and optical sensing technologies. While optical sensors employ variations in the characteristics of light to detect gases, nanosensors take advantage of the unique features of nanomaterials to increase sensitivity and selectivity. As a result, these technologies provide considerable advantages over conventional gas detection techniques as they advance.

Gas Analysis Techniques

1. Gas Chromatography (GC)

A common method for isolating and studying gas mixtures is gas chromatography. It is based on the differential migration of gas constituents through a stationary phase-filled column. Recent improvements in GC techniques and equipment include faster analysis times, better detection limits, and incorporating of various detection methods for increased analysis capabilities.

2. Mass Spectrometry (MS)

Mass spectrometry is a potent analytical tool for ionizing and separating gas molecules depending on their mass-to-charge ratios. For thorough gas analysis, it frequently works in tandem with gas chromatography. Higher resolution, enhanced sensitivity, and the ability to accurately analyze complicated gas mixtures are all results of improvements in MS techniques and equipment.

3. Fourier Transform Infrared (FTIR) Spectroscopy

FTIR spectroscopy is a non-destructive method for identifying and measuring gas molecules based on how well gas molecules absorb infrared light. This method is beneficial for locating and measuring dangerous air contaminants and trace gases. The development of portable, field-deployable devices and advances in spectral resolution and sensitivity are recent developments in FTIR methods and tools.

4. Emerging Analysis Techniques

The application of artificial intelligence (AI) and machine learning (ML) to gas analysis is growing, making it possible to comprehend large amounts of complex data more quickly and accurately. In addition, cutting-edge techniques for gas analysis are being investigated, such as terahertz spectroscopy and laser-induced breakdown spectroscopy, which may provide unique benefits for particular applications.

Integration of Gas Detection and Analysis Technologies

1. Smart Gas Detection Systems

Smart gas detection systems have emerged as a result of the integration of cutting-edge gas detection and analysis technologies, and they offer improved functionality, accuracy, and usability. These systems integrate advanced sensors, analytics, and communication capabilities to provide real-time monitoring, alarms, and data analysis.

2. Internet of Things (IoT) and Gas Detection

The IoT has transformed gas detection by enabling the integration of sensors and devices into a connected network. This connection allows remote monitoring, centralized data gathering, and advanced analytics to enhance the functionality of gas detection systems and guarantee prompt responses to possible dangers.

3. Remote Monitoring and Real-Time Data Analysis

For gas detection systems, improvements in wireless connection and cloud-based data storage have made it possible to monitor and analyze data in real-time remotely. This monitoring improves situational awareness and facilitates quick decision-making in response to potential threats by allowing operators and safety personnel to access crucial information anywhere.

4. Predictive Maintenance and Advanced Analytics

Systems for detecting gas now can do predictive maintenance thanks to integrating modern analytics and machine learning algorithms. This makes it possible to identify potential equipment problems early, which minimizes downtime and maintenance expenses while assuring the best system performance and safety.

Industry-Specific Applications

1. Oil and Gas Industry

Gas detection and analysis are essential in the oil and gas business to avoid accidents, maintain operational effectiveness, and adhere to environmental standards. Innovative technologies have enhanced the ability to detect leaks, monitor volatile organic compounds (VOCs), analyze emissions, and reduce environmental effects.

2. Chemical and Petrochemical Industry

Advanced gas detection and analysis techniques are crucial for monitoring dangerous gases, managing emissions, and maintaining chemical and petrochemical sector process safety. Advanced sensor and analytics integration has improved process control, increased safety precautions, and decreased environmental concerns.

3. Environmental Monitoring

Gas detection and analysis technology developments have substantially improved the ability to monitor the environment. By accurately detecting and quantifying air pollutants, greenhouse gases, and other harmful emissions, portable, low-power sensors and advanced analytics enable better decision-making and regulatory compliance.

4. Mining and Tunneling

Gas detection and analysis are essential for maintaining operational effectiveness and guaranteeing worker safety in mining and tunneling applications. Methane, carbon monoxide, and hydrogen sulfide are just a few examples of potentially dangerous gases that may be better monitored, lowering the chance of accidents and improving worker safety.

5. Emergency Response and Public Safety

Modern gas analysis and detection technology are essential for public safety and emergency response. First responders may identify and evaluate hazardous settings using portable, multi-gas detectors and real-time monitoring systems, ensuring their safety and promoting effective emergency management.

Future Trends and Challenges

1. Global Regulations and Safety Standards

International laws and safety norms are constantly changing to meet the demand for better environmental and safety monitoring. Therefore, businesses must stay current with these changes to ensure their gas detection and analysis technologies meet or exceed the necessary performance criteria.

2. Environmental Concerns and Sustainability

Greener, more energy-efficient gas detection and analysis technologies have emerged due to the increasing emphasis on sustainability and environmental preservation. Therefore, businesses must keep developing new ideas while concentrating on lowering the environmental effect of their processes and goods.

3. Technological Challenges and Limitations

While gas detection and analysis technology improvements have many advantages, they also bring up new difficulties and restrictions. To guarantee the dependability and accuracy of these detection systems, problems, including sensor drift, interference, and false alarms, must be resolved.

4. The Need for Continuous Innovation

Continuous innovation is necessary to keep ahead of the competition and satisfy the demands of many industries in the continually changing environment of gas detection and analysis technology. To produce novel, cutting-edge products that meet current difficulties and seize market opportunities, businesses must spend money on research and development.

Conclusion

It is impossible to overestimate the importance of gas detection and analysis in 2023, as technological breakthroughs will continue to increase environmental protection, efficiency, and safety across various industries. Gas detection systems have become effective instruments for in-the-moment monitoring and decision-making because of the integration of cutting-edge sensors, sophisticated analytics, and IoT connectivity.

Emerging technologies like nanosensors, optical sensing, and AI-driven analytics offer additional breakthroughs in the sector as we look to the future. However, to ensure these technologies’ dependability and correctness, businesses must also manage the difficulties and constraints they bring with them.

The gas detection and analysis field will have a promising future in 2023, with cutting-edge technology and methods holding great promise for improving operational effectiveness, environmental monitoring, and safety in various industries. As a result, gas detection manufacturing businesses may continue to offer efficient solutions that satisfy the changing needs of their clients and take on the urgent problems of our day by being at the forefront of innovation.