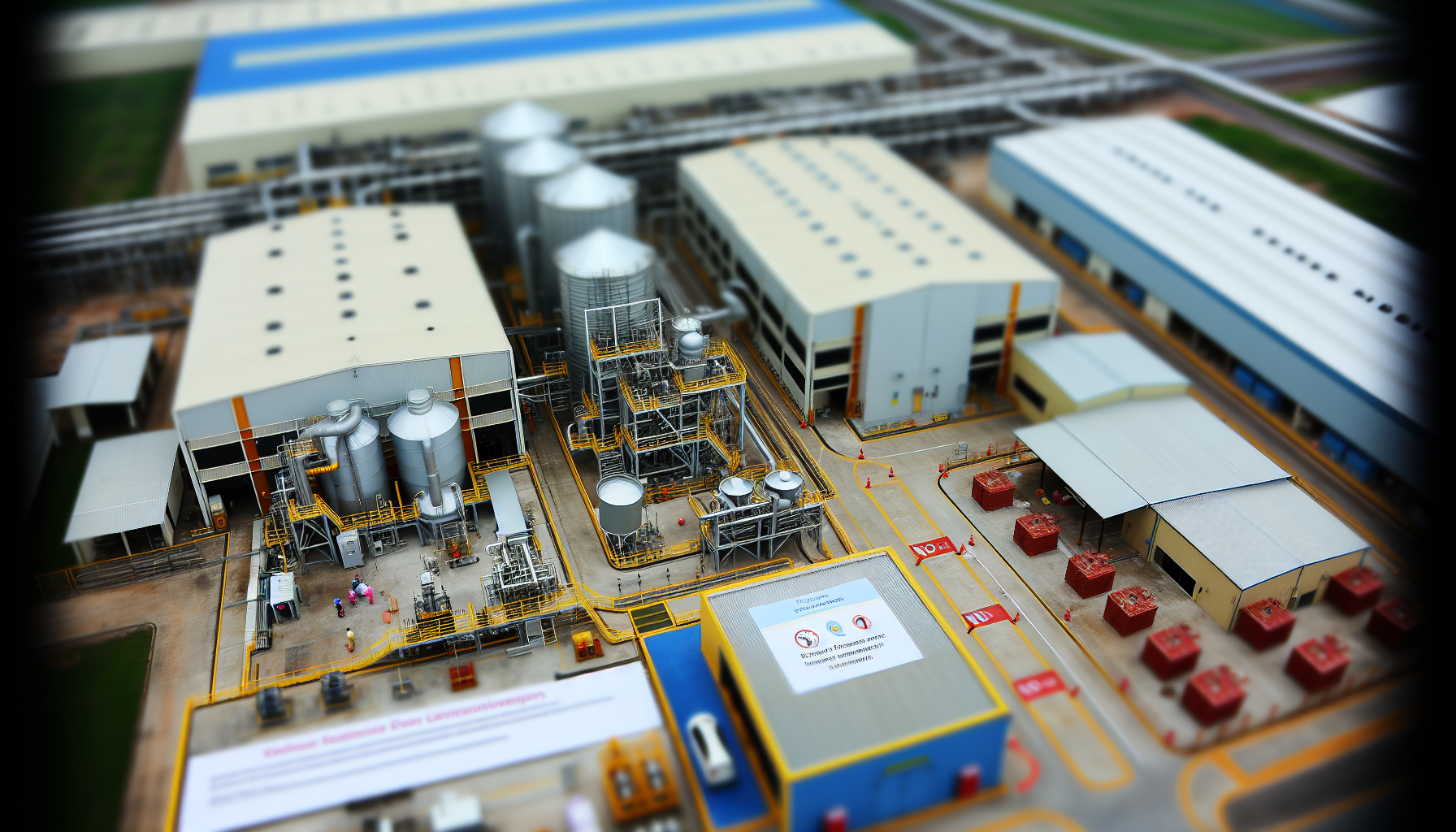

Nitrogen dioxide (NO2) is a well-known air pollutant that poses significant health risks in industrial settings. This brownish gas primarily arises from combustion processes, prevalent in various sectors, including manufacturing and chemical processing. The toxic properties of NO2 make it particularly dangerous; exposure can lead to acute respiratory issues and has been linked to long-term conditions such as asthma. Understanding these hazards is essential for maintaining safety in the workplace.

Industries at risk include those involved in diesel engine operation, coal-fired power generation, wastewater treatment, and various chemical manufacturing processes. The impact on human health and the environment from NO2 cannot be overstated. In particular, exposure to elevated levels can contribute to increased rates of respiratory illnesses, underscoring the need for rigorous monitoring and detection systems.

Identifying the Symptoms of Nitrogen Dioxide Overexposure

Detecting the symptoms of NO2 exposure is crucial for preventing serious health complications. Acute symptoms include shortness of breath, coughing, and irritation of the eyes and throat. High concentrations of NO2 can lead to severe symptoms and long-term consequences, such as potential permanent lung damage. These immediate effects serve as warnings that the air quality is compromised. Chronic exposure, however, may yield far graver consequences, such as long-term lung damage and the potential onset of chronic respiratory diseases.

Recognizing these symptoms early is essential. If not addressed promptly, acute symptoms can escalate to chronic issues, potentially culminating in irreversible damage to lung function. Without effective nitrogen dioxide monitoring, employees may unknowingly remain in hazardous environments, exacerbating their health risks. Thus, awareness and education about these symptoms are crucial components of workplace safety.

Assessing Air Quality: The Importance of Nitrogen Dioxide Monitoring

The effectiveness of nitrogen dioxide monitoring in the workplace is imperative for air quality management and ensuring worker safety. Regulatory bodies like the Occupational Safety and Health Administration (OSHA) have established strict exposure limits, notably a Permissible Exposure Limit (PEL) of 5 parts per million (ppm) averaged over an eight-hour work shift. These guidelines are crucial in preventing overexposure incidents, which can lead to severe health repercussions.

Regular monitoring of nitrogen dioxide levels serves not only to comply with these regulations but also as a proactive measure to safeguard employees. In the upcoming sections, we will delve deeper into implementing effective detection strategies, comparing portable and fixed systems, and outlining best practices for monitoring systems. Each aspect plays a vital role in creating an environment where employees can safely succeed.

Implementing Effective Nitrogen Dioxide Detection Strategies

To safeguard workers from nitrogen dioxide hazards, implementing effective detection strategies is essential. Several methods are available, including electrochemical sensors and semiconducting metal oxide sensors, each with distinct advantages and limitations. Electrochemical sensors, for example, offer high specificity and real-time detection capabilities, making them ideal for industrial settings where NO2 levels can fluctuate rapidly. However, they require regular calibration to ensure accurate readings, an important maintenance aspect for compliance and safety.

When comparing detection systems, portable and fixed units each serve vital roles. Portable detectors are particularly beneficial for immediate measurements at various locations, providing flexibility for dynamic work environments. On the other hand, fixed detection systems continuously monitor air quality and log data, essential for trend analysis and ensuring compliance with regulatory standards. Facilities that use a combination of both systems enhance their ability to capture real-time data and respond quickly to NO2 exposure events, demonstrating a proactive approach to worker safety.

Best practices for implementing monitoring systems include strategically placing detectors near potential NO2 sources, such as exhaust vents or areas of known combustion processes. Regular maintenance, including calibration and functional checks, further ensures the reliability of these systems. Organizations that prioritize these practices often note significant enhancements in their safety protocols, reducing the risk of overexposure incidents.

Training Employees on Nitrogen Dioxide Risks and Safety Protocols

Training employees on the risks of nitrogen dioxide is a critical step in fostering a culture of safety within industrial environments. Comprehensive training programs should cover the potential health hazards of NO2 exposure, including acute and chronic symptoms, and provide guidance on recognizing these symptoms early on. Additionally, it’s important that training includes the significance of regular calibration of sensors to maintain the effectiveness of monitoring systems. By building awareness, organizations empower their workforce to respond effectively to potential dangers.

Creating a culture of safety further involves integrating prevention strategies as well. Regular meetings, distribution of informative materials, and hands-on training exercises help to reinforce the importance of vigilance and compliance with safety protocols. Employees should become familiar with emergency measures for dealing with potential NO2 leaks or overexposure incidents, ensuring that swift and effective action can mitigate health risks.

Incorporating routine bump testing and calibration of monitoring devices into training ensures that workers are equipped to manage gas detection tools effectively, maintaining accuracy and reliability in monitoring nitrogen dioxide levels.

Interscan’s Role in Providing Effective Nitrogen Dioxide Monitoring Solutions

Interscan stands at the forefront of gas detection technology, offering advanced solutions tailored to meet the nitrogen dioxide monitoring needs of various industrial applications. With both portable and fixed detection systems based on electrochemical sensors, Interscan provides industry professionals with the necessary tools to ensure safe work environments. These systems deliver real-time readings, trace-level detection capabilities, and an innovative quick-exchange sensor system known as the ‘Interchange Sensor.’ This commitment to safety, reliability, and efficiency demonstrates how organizations can effectively address the challenges of nitrogen dioxide exposure and promote a culture of safety.

By investing in Interscan’s advanced gas detection technology and implementing robust training programs, organizations can significantly enhance their safety practices. This proactive approach not only ensures compliance with regulatory standards but also fosters an environment where employee health and safety are prioritized—ultimately leading to sustainable industrial success.

Recognizing nitrogen dioxide risks and implementing effective detection measures can profoundly impact workplace safety. By actively monitoring NO2 levels, training employees, and utilizing reliable detection systems like those offered by Interscan, organizations can mitigate the dangers posed by this hazardous gas, resulting in a healthier workforce and a more compliant industrial environment.