- Gases are one of the prominent occupational hazards in the textile industry.

- Several gases are used for various processes in fabric production, and some are produced as byproducts.

- The gases of concern are VOCs, dust, sulfur dioxide, nitrogen oxides, chlorine, ammonia, hydrogen sulfide, carbon monoxide, and dyes.

The textile industry is one of the top polluters affecting air, water, and soil. It ranks second in the use of hazardous substances. Many of these chemicals are dangerous gases, which are serious occupational hazards affecting the health and safety of workers in this vast industry. Find out what these gases are, and if your textile unit could have these hazards, and should be controlling them.

Sources of Hazardous Gases in the Textile Industry

The textile industry uses raw materials from various sources, including agriculture, natural resources like forests, and fossil fuels. Cotton, linen, jute, and hemp are grown. Rayon and Tencel are produced from wood pulp, while synthetic fabrics, polyester, and nylon are made from fossil fuels.

The textile industry’s main environmental impact is water pollution. Next in importance are the gaseous emissions. The global textile industry, valued at $660.13 billion in 2025, is expected to grow at a CAGR of 6.8% until 2029 and employ an increasing number of people, who need to be protected from gaseous occupational hazards.

Sourcing can be polluting; however, the processes in textile industrial facilities can produce many hazardous gases during the processing of raw materials to manufacture the fabrics.

Manufacturing Processes

Gaseous emissions are produced through stack or non-point emissions. Stacks are tall chimneys that remove and release the gases into the air. The gases released through stacks end up as environmental pollution that can harm neighborhoods and the air. It leads to acid rain, smog, eutrophication, global warming, climate change, and damage to the stratospheric ozone.

Non-point sources release gases in the workplace and become occupational hazards for workers.

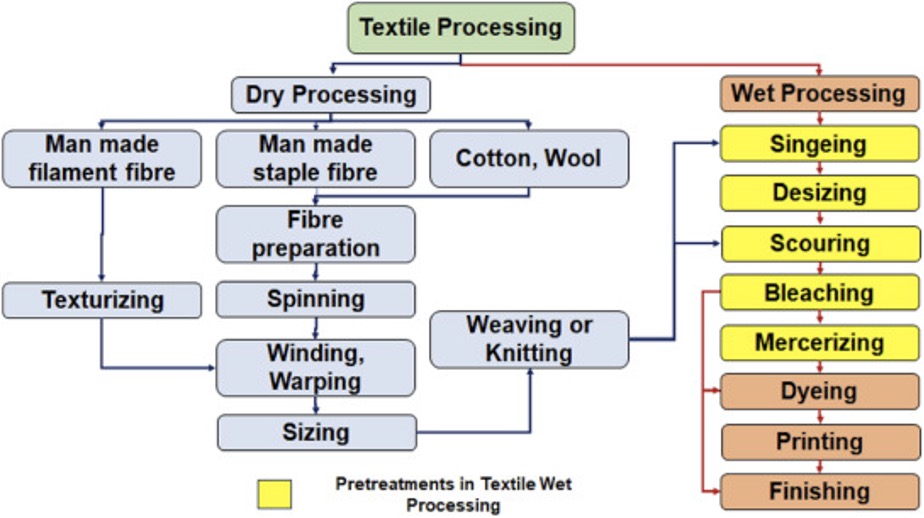

Several textile manufacturing processes either use or emit hazardous gases, such as those involved in processes like spinning, weaving, wet processing (dyeing, printing, and finishing), etc.; see Figure 1. Each stage uses energy, fuel, and chemicals that can cause occupational hazards. It can cause a wide range of health effects, from skin irritation to respiratory problems and even cancer.

Figure 1: Textile process flow, Panda, et al. (2021). (Image credits: https://doi.org/10.1016/j.jclepro.2021.129725)

-

Volatile Organic Components

Volatile organic components (VOCs) are organic carbon compounds that are liquids but have a low boiling point and can vaporize at room temperature and pressure. VOCs are used during the manufacture of yarns, fibers, and fabrics. These can be hydrocarbons used as solvents, finishes, and dyes in several textile manufacturing processes. The most common VOCs in the textile industry are formaldehyde and toluene. Other VOCs emitted are amides- formamide and N, N-dimethylformamide. VOCs can accumulate to dangerous levels in enclosed spaces and areas with limited ventilation.

VOCs are known hazardous indoor pollutants that are toxic and affect people. VOCs produce ground-level ozone that is toxic to people. It causes coughing and wheezing, and chronic exposure causes cancer.

Formaldehyde

Formaldehyde is the main VOC produced and is present because it is used for many processes and occurs as an emission from substances like dyes.

- Uses: Formaldehyde is used in finishing to make fabrics wrinkle-free and waterproof, and as a color-fastener.

- Emission: Dyes can evaporate during drying, hardening, and heat pick phases to release formaldehyde and acetic acid.

Formaldehyde has adverse health effects, including dizziness, skin irritation, and headaches, as well as cancer due to long-term exposure.

-

Azo Dyes

Dyes are used as powders and are present in the dust that exists due to fabrics and machinery, which can be inhaled by textile workers, exposing them to their adverse effects. Workers can also absorb the dyes through contact when proper personal hygiene is not practiced. Moreover, as mentioned, some dyes also produce formaldehyde in batch coloring.

Azo is the most common synthetic dye. These and other reactive dyes used for a wide range of fibers are toxic, mutagenic, and carcinogenic. The dyes can cause nasal, lung, and urinary cancers and harm red blood cells. These problems exist regardless of the fabrics being produced.

-

Dust

Dust is a major problem in all textile industries, but it is significant in the cotton industry. Dust is produced from cotton, other fabrics, and machines, and carries various chemicals.

Fiber dust: Dust is produced during spinning and weaving, and the dust levels can be high in factories producing yarn. Cotton yarn production creates dust that is laden with fine fibers and the pesticides used during crop growth. The resins in cotton can also cause health problems.

Inhaling dust laden with natural (cotton, jute, etc.) and synthetic fibers causes byssinosis or brown lungs, classified as an occupational lung disease. The fibers and associated chemicals can affect workers, causing coughing, chest tightness, shortness of breath, and hysteria. Chronic exposure reduces pulmonary function and is very harmful, especially for people who already have asthma.

Particulate matter: Fine particulate matter (PM2.5) made of materials equal to or less than 2.5 microns is produced as a result of burning fuels- wood, gasoline, diesel, and coal. PM2.5 is produced directly from the fires or as secondary particles from sulfur dioxide, nitrogen dioxide, and certain organic compounds. Fine PM is a health concern as an indoor and outdoor pollutant, as it can enter the lungs through breathing to cause tissue damage and lung inflammation, resulting in bronchitis, asthma, and restriction of activity. The PM dust is prevalent in all areas of a textile facility that burns fuels.

PFAS: Per-and polyfluoroalkyl substances (PFAS) represent a set of chemicals that have 9200 different structures. They are used in textiles to repel water, stains, dust, and oil, and as a flame retardant in the finishing stages with other compounds. Besides being in wastewater, it can be found as airborne particles and is part of the dust in textile manufacturing units.

Due to labor division along gender lines, women can be more exposed to organic dusts than men and suffer more from associated diseases.

-

Sulfur Dioxide

Sulfur Dioxide (SO2) is a standard byproduct gas produced during the combustion of wood and fossil fuels, so practically all textile facilities must monitor this gas. Many processes in the textile industry are energy-intensive and consume large amounts of fuel. Boilers used to make steam and hot water for dyeing, drying, printing, and humidification also release SO2. Chemicals used in printing and finishing can also produce SO2.

SO2 is very toxic as it is reactive and corrosive. Workers can be exposed through inhalation or contact, which can cause serious health effects due to acute and chronic exposure. It affects the eyes, skin, and the respiratory system.

-

Nitrogen Oxides

Besides SO2, nitrogen oxides (NOx) are also produced during the combustion of wood, coal, and oil. Around 95% is composed of nitrogen dioxide (NO2) and nitric oxide (NO). First, NO is produced, which is oxidized further to give NO2. Several dyes and chemicals used in printing and finishing emit nitrogen oxides when heated. It is also produced in boilers and the processes such as printing, dyeing, and drying. Nitrogen oxides can injure lung tissue and can cause premature death in severe cases.

SO2 and nitrogen oxides are the common gases produced. For example, the two gases together account for 20% of the total gaseous emissions in the Chinese textile industry.

-

Chlorine and Its Compounds

Chlorine (Cl2) is found in many of the bleaches used in the textile industry to remove discoloration and unwanted colors, for disinfection, odor removal, and deep cleaning. One of the main problems is that workers exposed to chlorine gas suffer from smell function disturbance 6.33 times more than people not exposed to the gas. When inhaled, it can irritate the nose and respiratory system, which leads to lung damage in extreme cases or pulmonary edema. It also burns skin and eyes and can be absorbed through the skin. Very high levels of chlorine gas can be lethal.

Chlorine dioxide (ClO2) is also used as a bleaching agent and can be released during dyeing and bleaching. ClO2 is a strong oxidizer that irritates the respiratory system, skin, and eyes. Moreover, the gas can be explosive if present in air at concentrations above 10% v/v.

-

Hydrogen Sulfide

Hydrogen sulfide (H2S) gas is released during the dyeing and bleaching phases. The gas is produced as a byproduct in viscose rayon manufacturing factories due to decaying organic matter. The gas is highly toxic and can be lethal immediately at 1000-2000 ppm (parts per million). It is a colorless gas that smells of rotten eggs at lower concentrations. At higher concentrations, where it is hazardous, it causes smell paralysis. Besides being toxic, H2S is also flammable.

-

Carbon Monoxide

Carbon monoxide (CO) is released during the incomplete combustion of fuels (coal, wood, and oil) to run machinery and heat boilers. So, the gas can be released in several places in the textile industry and during processes that require heat, steam, or hot water.

CO combines with hemoglobin to reduce oxygen transport, causing hypoxemia and CO poisoning, with symptoms such as headaches, dizziness, weakness, and nausea. Chronic exposures can exacerbate existing respiratory diseases, and strong acute exposures can be lethal.

-

Ammonia

Ammonia liquid is used to treat cotton fabric and wool to make it shrink-resistant, anti-wrinkle, and improve its appearance. Ammonia (NH3) also enhances the physical and mechanical properties of cotton fibers. The liquid is used in a process called mercerization to enhance strength and dye uptake for cotton. For wool and silk, it helps in regulating pH for bleaching processes.

NH3 is also used as a gas for various cellulosic fibers, polyester, rayon, and various blends for improving KES shearing, bending, and crease recovery.

NH3 can be released during its use and can irritate skin, eyes, and the respiratory system when inhaled. Ammonia toxicity depends on exposure concentrations and duration. Ammonia is also flammable.

Mitigating Gaseous Occupational Hazards

The gases that are occupational hazards are regulated by strict national, regional, and local standards due to their toxicity. Textile facilities must conduct a risk assessment to find out which gases exist in their facilities and in what concentrations. Then, the industrial hygienists must ensure that the levels of these gases, whether used as raw materials or generated as byproducts, always remain below permitted levels. The best means of achieving this aim is to utilize the hierarchy of controls, which involves eliminating risks, reducing risks, using engineering controls, administrative controls, and personal protective equipment to protect workers.

Monitoring the air for these gases by strategic placement of gas analyzing sensors can alert staff to toxic gases that exceed permitted levels, enabling evacuation measures and corrective action.

The gas sensors must be precise enough to detect and measure gas in ppm levels, since many are dangerous in these amounts. Interscan offers fixed and portable gas sensors for many of the toxic gases found in textile industries.

Book a consultation with Interscan to learn more about our fixed and portable gas analyzers for your industrial hygiene needs.

Source

California Air Resources Board. (n.d.). Inhalable Particulate Matter and Health (PM2.5 and PM10). Retrieved from https://ww2.arb.ca.gov/resources/inhalable-particulate-matter-and-health

Drumond Chequer, F. M., de Oliveira, G. A. R., Anastacio Ferraz, E. R., Carvalho, J., Boldrin Zanoni, M. V., & de Oliveir, D. P. (2013). Textile Dyes: Dyeing Process and Environmental Impact. InTech. doi: 10.5772/53659

E-Facts. (2022). Occupational safety and health in the textiles sector. Retrieved from https://vzd.mddsz.gov.si/document-download/occupational-safety-and-health-in-the-textiles-sector-2022-01-14-246

Forida P, Shariful I, Zakia U, Shaharia A, AKM Saiful I. A Study on the Solutions of Environment Pollutions and Worker’s Health Problems Caused by Textile Manufacturing Operations. Biomed

J Sci & Tech Res 28(4)-2020. BJSTR. MS.ID.004692.

Guo, Y., Zhu, L., Wang, X., Qiu, X., Qian, W., & Wang, L. (2022). Assessing environmental impact of NOX and SO2 emissions in textiles production with chemical footprint. Science of The Total Environment, 831, 154961. https://doi.org/10.1016/j.scitotenv.2022.154961

International Labour Organisation. (1984). OCCUPATIONAL SAFETY AND HEALTH IN THE

TEXTILES INDUSTRY. Retrieved from https://webapps.ilo.org/public/libdoc/ilo/1984/84B09_228_engl.pdf

Lellis, B., Fávaro-Polonio, C. Z., Pamphile, J. A., & Polonio, J. C. (2019). Effects of textile dyes on health and the environment and bioremediation potential of living organisms. Biotechnology Research and Innovation, 3(2), 275-290. https://doi.org/10.1016/j.biori.2019.09.001

Mekala, K., Malki, A., Amarasinghe, D. P. N. T., & Ishara, G. (2023). Occupational Health and Safety in the textile industry. J. Res. Technol. Eng, 4, 127-140.

Mehr, H. G., Torabiardekani, N., & Rahimpour, M. R. (2023). Ammonia application in fabric, textile, and leather products. Progresses in Ammonia: Science, Technology and Membranes, 223-239. https://doi.org/10.1016/B978-0-323-88501-0.00006-9

Mohapatra, P., & Gaonkar, O. (2021). An overview of toxic chemicals in textiles. New Delhi, India: Toxics Link, 41.

New Jersey Department of Health. (2015, October). Hazardous Substance Fact Sheet- Chlorine. Retrieved from https://nj.gov/health/eoh/rtkweb/documents/fs/0367.pdf

Panda, S. K. B. C., Sen, K., & Mukhopadhyay, S. (2021). Sustainable pretreatments in textile wet processing. Journal of Cleaner Production, 329, 129725. https://doi.org/10.1016/j.jclepro.2021.129725

Pinto, V. C., & Peleg Mizrachi, M. The Health Impact of Fast Fashion: Exploring Toxic Chemicals in Clothing and Textiles. Encyclopedia, 5(2), 84. https://doi.org/10.3390/encyclopedia5020084

Rianto, B. U. D., Purnomo, W. S., & Sastrowijoto, S. (2019). The Smell Function Disturbance in Textile Industrial Workers Exposed to Chlorine Gas. Biomedical Journal of Scientific & Technical Research, 18(3), 13551-13555.

Tounsadi, H., Metarfi, Y., Taleb, M., El Rhazi, K., & Rais, Z. (2020). Impact of chemical substances used in textile industry on the employee’s health: Epidemiological study. Ecotoxicology and Environmental Safety, 197, 110594. https://doi.org/10.1016/j.ecoenv.2020.110594

WHO. (2002). Concise International Chemical Assessment Document 37- CHLORINE DIOXIDE (GAS). Retrieved from https://iris.who.int/bitstream/handle/10665/42421/a73566.pdf