- Permit confined spaces can accumulate gases and substances that can be hazardous for workers as they can lead to explosions, harm, and even death.

- The four toxic gases to monitor in a confined space before entry and during work are oxygen, carbon monoxide, hydrogen sulfide, and flammable gases.

- Portable gas analyzers designed for the purpose, operated by trained personnel, can eliminate or reduce the risks of working in confined spaces.

Safety and facility managers must ensure that staff are not exposed to risks due to toxic gases in their workplace. Monitoring and controlling toxic gases ensures their levels stay within permissible limits. In this article, read about toxic gases in confined spaces and how to monitor them.

Gas risks in Confined Spaces

Confined spaces are large enough for employees to enter and perform assignments, and there are two types.

Non-Permit Confined Spaces do not develop a hazardous atmosphere that can pose an occupational danger to workers.

Permit Confined Spaces are those where the enclosed nature can potentially create hazardous conditions leading to harm and accidents requiring emergency action, and can occur in the three following scenarios.

- Limited openings for exit and entry of people. The openings are small, and where it is not possible to wear life-saving equipment or remove injured workers in folded or bent positions. Sometimes larger openings’ size is reduced by structures like ladders.

- Insufficient natural ventilation. Due to a lack of air circulation, the atmosphere in confined spaces differs from usual. This can occur due to the accumulation of deadly gases or the decomposition of organic matter, increasing levels of flowing liquids, and excessive temperature.

- Spaces not meant for continuous worker occupancy. Confined spaces are not meant for regular work but only for inspections, repair, maintenance, and cleanup. Confined spaces are meant for storing products and processing or transporting materials. Manufacturing processes often use toxic substances, which release toxic gases. Chemical and biological reactions can also be sources of toxic gases.

Some common confined spaces where toxic gases accumulate are listed below:

- Boilers, furnaces, and degreaser

- Pumping station, pipeline, and pits

- Reactors or processing mills

- Shafts and trenches

- Storage tanks, silos, and barges

- Septic tank and sewage digestor

The hazardous atmosphere created by confined spaces and their functions can cause injury, illness, incapacitation, impaired ability to escape, or even death.

The Toxic Gases in Confined Spaces

Gas concentrations in the atmosphere outside the permissible exposure limit (PEL) are considered toxic and hazardous to people. The typical gases that accumulate in confined spaces and are hazardous to people are oxygen, hydrogen sulfide, carbon monoxide, and combustible gases.

Atmospheric conditions in permit confined spaces must be below the PEL, or threshold limit value (TLV) or time-weighted average (TWA) of a substance, as per the US Occupational Safety and Health Administration (OSHA) regulations 29 CFR 1910.146.

Oxygen

The first atmospheric condition that is harmful to people is oxygen depletion. The usual oxygen (O2) level in the atmosphere is 20.9 percent. Atmospheric oxygen levels below 19.5 percent and above 23.5 percent are hazardous to people.

O2 depletion is the leading cause of death in confined spaces. O2 levels can fall in confined spaces because they are used in chemical reactions, such as burning or rusting. In some cases, damp steel also absorbs O2 from the air. Biological reactions like organic matter decomposition will also use O2. Displacement through other gases is another reason for O2 depletion in confined spaces. According to OSHA, O2 depletion results in the effects described in Table 1.

Table 1: Effect of various oxygen deficiency levels, OSHA. (Credits: Hazards of Confined Spaces)

| Oxygen Deficiency levels | Health Effects on People |

| 19.5 % | Minimum permissible oxygen level. |

| 16-19% | Decreased ability to work strenuously. It may impair coordination and induce early symptoms in persons with coronary, pulmonary, or circulatory problems. |

| 13-6% | Respiration increases in exertion, pulse up, and impaired coordination, perception, and judgment. |

| 10-13% | Respiration increases in rate and depth; there is poor judgment and blue lips. |

| 8-10% | Causes mental failure, fainting, nausea, ashen face, unconsciousness, blue lips, nausea, and vomiting. |

| 6-8% | 8 minutes – fatal

6 minutes – 50% fatal, 4-5 minutes – possible recovery. |

| 4-6% | Coma in a minute, convulsions, and death |

O2 enrichment can occur when pure O2 replaces ambient air. Some operations use pure O2, but opening a tank of pure O2 in confined spaces changes the atmosphere. If there are any preexisting combustible materials in the confined spaces, it leads to fire and explosion risks. Materials that generally do not burn will ignite in O2-enriched atmospheres.

Combustible Atmospheres

Combustible atmospheres arise due to combining O2, flammable material, and dust. Certain gas mixtures are produced due to natural decay and will also lead to combustion. Several confined spaces like tanks and pipelines can have leakages or remains of previous contents of flammable liquids like gasoline. Ignition sources that set off a fire can be sparks from electric tools, welding, cutting, or even smoking.

The common flammable gases in confined spaces are solvent vapors, paint vapors, carbon monoxide, methane, gasoline, and hydrogen sulfide. Besides being a fire risk, solvents (like kerosene and paint strippers) can also lead to health harm like dizziness, lack of concentration, drowsiness, headaches, confusion, coma, and death.

Gases and vapor have a lower explosive limit (LEL) below which they don’t burn and an upper explosive limit (UEL) above which combustion doesn’t occur. The limit differs for each gas according to OSHA, as shown in Table 2.

OSHA sets the permissible exposure limit (PEL) for combustible gases in confined spaces at 10% below the LEL of any gas. The limit for airborne dust is levels that obscure vision at distances of or less than 5 feet (1.52 m).

Table 2: Lower explosive limit (LEL) and upper explosive limit (UEL) of combustible gases commonly occurring in confined spaces, OSHA. (Credits: Hazards of Confined Spaces)

| Flammable Vapor or Gas | LEL | UEL |

| Acetylene | 2.5% | 100.0% |

| Carbon Monoxide | 12.5% | 74.0% |

| Gasoline | 1.3% | 7.1% |

| Hydrogen Sulfide | 4.3% | 46.0% |

| Natural Gas | 3.8% | 17.0% |

| Propane | 4.5% | 14.5% |

Carbon Monoxide

Carbon monoxide (CO) is a colorless, odorless gas formed due to the burning of carbon-based fuels. It can be found in confined spaces due to malfunctioning or improperly-vented gas appliances.

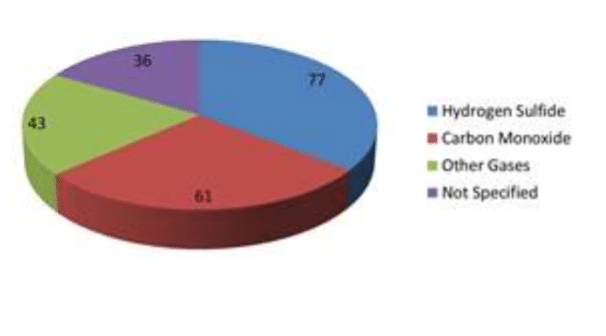

Besides being a fire hazard, Carbon monoxide is harmful to people as it inhibits the ability of blood to carry oxygen and limits O2 delivery to organs. People can go through a series of conditions showing different symptoms based on dosage and time of exposure, such as fatigue, confusion, headache, nausea, heart palpitations, and unconsciousness. Even short exposures can lead to harm to people with cardiovascular problems. At high concentrations, people can collapse. CO was responsible for 61 percent of confined space fatalities in 2018, see Figure 1.

The United State Environment Protection Agency (EPA) reports various permissible exposure levels of CO; anything over this level can be harmful, even after short exposures.

- According to OSHA, the PEL is 50 ppm (parts per million) for eight hours in confined spaces at an 8-hour time-weighted average (TWA).

- The National Institute for Occupational Safety and Health (NIOSH) recommends PEL of 35 ppm CO as an 8-hour TWA and 200 ppm as the ceiling, based on the risk of cardiovascular effects.

Figure 1: Most common hazardous causes in confined space deaths, Koester, 2018. (Image credits: https://ohsonline.com/articles/2018/08/01/we-must-change-the-statistics-of-confined-space-injuries-and-fatalities.aspx)

Hydrogen Sulfide

Hydrogen sulfide (H2S), also called “sewer gas,” is a colorless gas and smells like rotten eggs at low concentrations. It is produced due to the decomposition of organic materials in rayon textile factories, wastewater treatment industries, petroleum and natural gas work sites, and agricultural manure pits.

Besides being a flammable gas, H2S results in a loss of sense of smell, leading people to think there is no gas left in confined spaces. H2S is an irritant, acts as an asphyxiant, and affects the central nervous system.

- Low levels of H2S cause eye, nose, throat, and respiratory tract irritations, and effects can appear after hours or days; repeated exposure causes fatigue, insomnia, weight loss, etc.

- Moderate levels cause headache, dizziness, nausea, staggering, and excitability.

- High levels of H2S within one to a few breaths cause shock, convulsions, breathing problems, coma, and death.

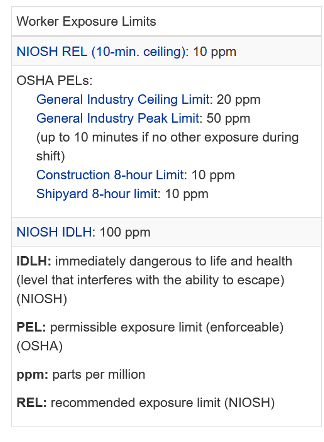

The PEL levels are detailed in Table 3 below. OSHA PEL is 20 ppm, and H2S concentrations of and above 100 ppm are Immediately Dangerous to Life and Health (IDLH).

H2S accounted for 77 percent of confined space fatalities, see Figure 1.

Table 3: Worker Exposure Permissible Exposure Limits for Hydrogen Sulfide, OSHA. (Credits: https://www.osha.gov/hydrogen-sulfide/hazards)

To mitigate risks in confined spaces, monitoring gas levels is a must.

How to Monitor Toxic Gases in Confined Spaces?

Around 60 percent of deaths in confined spaces are of potential rescuers; in all cases, one of the procedural failures was an absence of testing before entry. To avoid explosions or asphyxiation, testing confined spaces before entering them, even for a few moments of work, testing is necessary.

Every testing should include the following three steps according to OSHA:

- Oxygen should be the first gas tested as combustible gas meters are oxygen dependent and do not function in an O2-depleted atmosphere.

- Second, test for combustible gases such as fire and explosions, as these immediately threaten life.

- Next, check for toxic gas and vapors.

While conducting atmosphere tests, the purpose of the confined space and possible gases that could accumulate must be kept in mind. Also, consider proximity to nearby automobiles and traffic. Tests must be carried out by trained personnel capable of interpreting the device readings.

Besides testing before entry, the atmosphere must be monitored while working in confined spaces.

Instruments are Recommended

Using instruments for gas analysis to detect hazardous gases is essential since manual detection is impossible. OSHA recommends portable direct-reading gas monitors to ensure worker safety. Interscan has the GasD® 8000 portable gas analyzer series offering gas detectors for CO and H2S from 0 to 2000 ppb (Parts per billion). Check the OSHA recommendations for detailed instructions on how to conduct confined space tests.

Sources

EPA. (2022, Aug, 26). Carbon Monoxide’s Impact on Indoor Air Quality. Retrieved from https://www.epa.gov/indoor-air-quality-iaq/carbon-monoxides-impact-indoor-air-quality

Health and Safety Authority. (n.d.). Working in Confined Spaces. Retrieved from https://www.hsa.ie/eng/topics/confined_spaces/#cs

Koester, C. (2018, Aug 1). We Must Change the Statistics of Confined Space Injuries and Fatalities. Retrieved from https://ohsonline.com/articles/2018/08/01/we-must-change-the-statistics-of-confined-space-injuries-and-fatalities.aspx

Occupational Safety and Health Administration. (2019). Confined Spaces. Retrieved from https://www.osha.gov/sites/default/files/2019-03/confinedspace.pdf

Occupational Safety and Health Administration. (n.d.). Permit-Required Confined Spaces. Retrieved from https://www.osha.gov/sites/default/files/publications/osha3138.pdf

OSHA Fact Sheet, (2005, Oct). Hydrogen Sulfide (H2S). Retrieved from https://www.osha.gov/sites/default/files/publications/hydrogen_sulfide_fact.pdf

Toxic gases. (n.d.). Retrieved from https://www.sc.edu/ehs/training/Confined%20Space/06_toxic.htm