Nitrogen dioxide (NO2) is a colorless gas with a characteristic sharp odor that poses significant health risks, particularly in industrial settings. Exposure to nitrogen dioxide is especially prevalent in industries such as oil and gas extraction, petrochemical production, and manufacturing, where emissions can lead to serious environmental and health consequences, including the formation of acid rain.

The importance of nitrogen dioxide detection cannot be overstated. In environments where this toxic gas is present, monitoring is important. Regulatory bodies like OSHA have established stringent permissible exposure limits (PEL) of 5 ppm as an eight-hour time-weighted average (TWA) for NO2. Ensuring compliance with these regulations is vital not only for worker safety but also for operational integrity and liability management.

Identifying the Limitations of Traditional Gas Detection Methods

Despite the necessity of effective NO2 detection, traditional gas monitoring methods face notable challenges. One significant issue is the accuracy and reliability of older detection technologies. Many of these systems struggle to deliver timely and precise readings of nitrogen dioxide levels, which can jeopardize worker safety. The lack of sensitivity in older detectors can result in undetected low-level exposures that contribute to long-term health problems.

Furthermore, inadequate detection can lead to compliance issues with health and safety standards. For instance, in case of hazardous leaks, failure to meet detection requirements might not only put employees at risk but could also result in costly fines and regulatory repercussions.

The need for more advanced detection solutions has never been more pressing, and that’s where the comparison between portable and fixed nitrogen dioxide detectors comes into play.

Comparing Fixed vs. Portable Detectors for Effective Nitrogen Dioxide Detection

When it comes to NO2 detection, both fixed and portable detectors offer unique advantages depending on the application and specific needs of the industrial setting.

Exploring the Advantages of Fixed Detectors for Continuous Monitoring

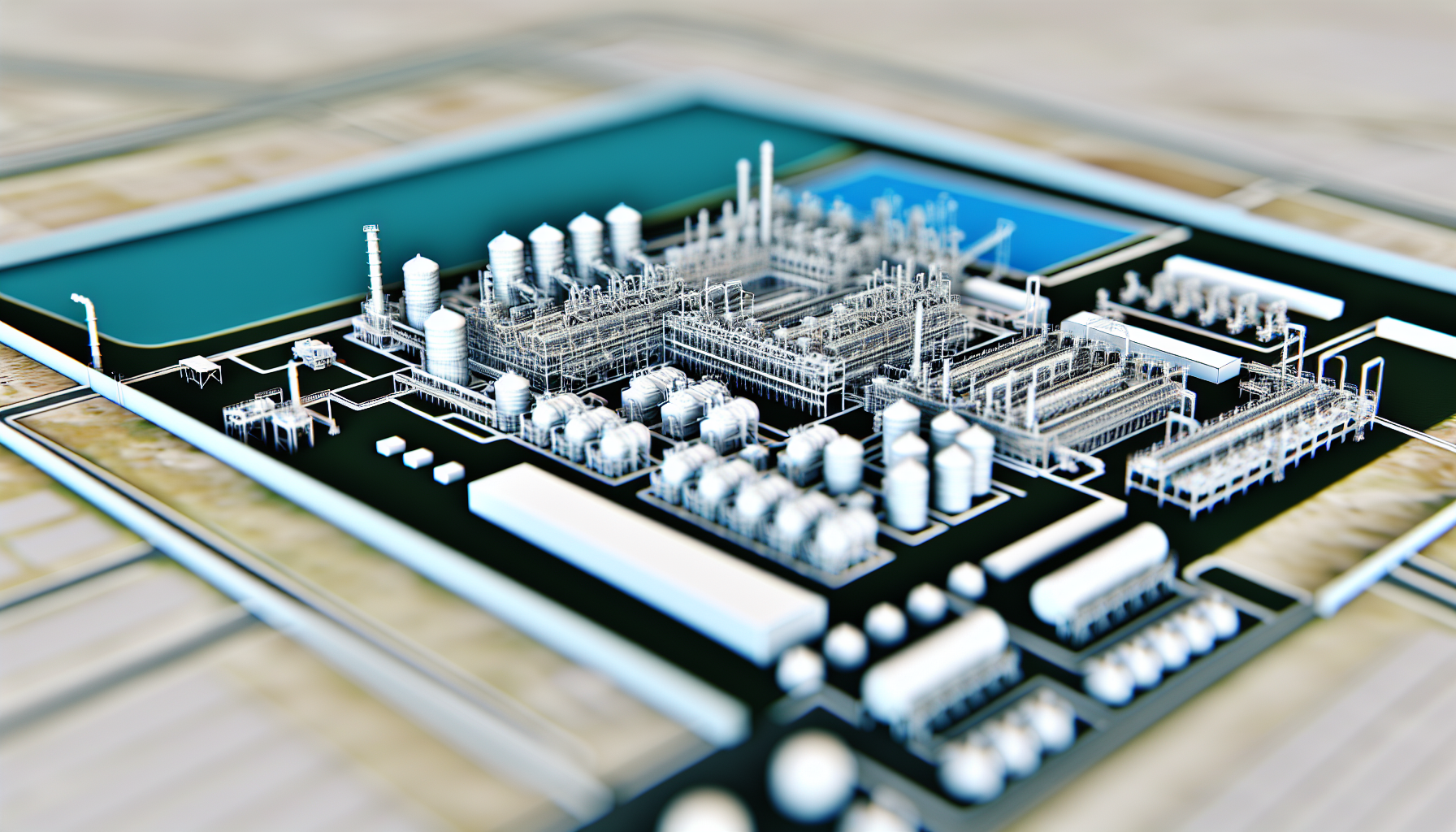

Fixed nitrogen dioxide detectors are designed for consistent monitoring, making them a valuable asset in areas where NO2 exposure is both persistent and predictable. These systems provide 24/7 surveillance, ensuring any deviations from acceptable levels are immediately detected and acted upon. This is particularly beneficial in large facilities where consistent exposures can occur, such as chemical plants and manufacturing sites.

Moreover, fixed detectors often feature automated data logging capabilities, allowing for historical data analysis and trend identification. Fixed systems can lead to improved compliance. For many facilities, integrating fixed detectors into a facility-wide alarm system enhances overall safety and operational readiness.

Assessing the Benefits of Portable Detectors for Versatile Use

On the other hand, portable nitrogen dioxide detectors offer flexibility and mobility. These systems are essential for workers who enter confined spaces, undertake temporary jobs, or conduct maintenance activities in various locations. The ability to carry a detector allows for immediate responsiveness in situations where stationary systems might not reach.

Real-time data collection from portable detectors can prove invaluable in dynamic environments. They provide on-the-spot readings that can help assess immediate risks and inform safety decisions as conditions change. This versatility ensures that personal safety is prioritized, particularly in areas where the risk of nitrogen dioxide exposure can fluctuate significantly.

While portable detectors require regular calibration and maintenance for accurate readings, their role in enhancing worker safety should not be underestimated. Having both fixed and portable detectors as part of a comprehensive safety strategy covers a wider range of scenarios and threats, providing peace of mind for both employers and employees.

Evaluating the Impact of Environment on Detector Performance

Selecting the appropriate nitrogen dioxide detector requires consideration of environmental factors that can impact performance. As we navigate through various industrial settings, temperature, humidity, and gas concentration are critical variables that can affect the accuracy and reliability of both fixed and portable detectors. For fixed detectors, optimal placement is vital; they must be situated in areas with expected gas accumulation while avoiding extreme conditions that could hinder performance.

Portable detectors, while mobile, also demand regular calibration to account for variations in environmental conditions. In humid environments or locations with high temperature fluctuations, the accuracy of readings can diminish without consistent maintenance, thereby jeopardizing compliance with safety regulations. Regardless of the detector type, ensuring you select a system that can withstand the demands of the unique industrial landscape is crucial for ongoing safety and compliance.

Making an Informed Decision: Choosing the Right NO2 Detection Solution

When it comes to making an informed decision regarding NO2 detection, several key considerations arise. First, assess the scale of your operations and evaluate personnel exposure risks, especially in high-risk industries. Consider whether the majority of exposures occur in a fixed location, which would favor the implementation of fixed detectors, or if work typically occurs in varying locations, thereby necessitating portable options to ensure consistent monitoring.

Additionally, cost versus benefit analysis plays a vital role. While the initial investment in fixed detectors may be higher, their long-term capabilities—including data logging and integration with alarm systems—can lead to more significant savings in incident management and compliance costs. Maintenance and training costs should also be factored into your decision-making process to ensure that your workforce is adequately prepared to handle either system.

Interscan Solutions for Reliable Nitrogen Dioxide Detection

To navigate the complexities of nitrogen dioxide detection effectively, Interscan offers cutting-edge fixed and portable detection solutions designed to meet the specific needs of various industrial environments. Utilizing advanced electrochemical sensors, our systems provide real-time readings, trace-level detection, and feature a quick-exchange sensor system known as the ‘Interchange Sensor.’ By investing in Interscan’s innovative technology, you can enhance workplace safety and effectively address the challenges associated with toxic gas exposure, ensuring a compliant and secure work environment.

The integration of both fixed and portable nitrogen dioxide detectors within an industrial safety strategy is essential for maintaining worker health and regulatory compliance. By leveraging both systems, professionals can create a comprehensive safety net that safeguards employees against the hazards posed by nitrogen dioxide, enhancing organizational integrity and productivity.