“Dew Point” is defined as the temperature to which a given volume of air must be cooled at constant pressure and constant water vapor content in order for saturation to occur. If the air is cooled further, some of the moisture will condense.

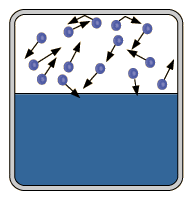

The notion of “Saturated Vapor Pressure” can be understood by considering the process of evaporation in a closed container of water, with some air above the liquid. Evaporation will proceed until there are as many molecules returning to the liquid as there are escaping. At this point the vapor is said to be saturated, and the pressure of that vapor (usually expressed in millimeters of mercury [mmHg]) is called the saturated vapor pressure.

Since the molecular kinetic energy is greater at higher temperature, more molecules can escape the surface and the saturated vapor pressure is correspondingly higher. If the liquid is open to the air, then the vapor pressure is seen as a partial pressure along with the other constituents of the air.

For the sake of completeness, “Relative Humidity” is defined as the ratio of the partial pressure of water vapor in a gaseous mixture of air and water vapor, to the saturated vapor pressure of water—at a given temperature.

Relative humidity is expressed as a percentage and is calculated as follows:

![]()

Where

![]() is the relative humidity of the gas mixture being considered

is the relative humidity of the gas mixture being considered

![]() is the partial pressure of water vapor in the gas mixture

is the partial pressure of water vapor in the gas mixture

![]() is the saturation vapor pressure of water at the temperature of the gas mixture

is the saturation vapor pressure of water at the temperature of the gas mixture

As you can see, while relative humidity might be a useful benchmark for weather reporting, dew point is the parameter of choice when one is concerned about condensation in a gas sample to be analyzed—especially one coming from a process stack.

Condensation can foul sampling lines, harm instruments, and in many cases can dissolve a portion of the very sample you are trying to analyze. For example, such gases as bromine, chlorine, chlorine dioxide, formaldehyde, hydrogen chloride, hydrogen peroxide, nitrogen dioxide, peracetic acid, and sulfur dioxide are all quite soluble in water.

Given the dew point of the sample in question, you will immediately know that once it is brought to a temperature below this, condensation will occur.

OK, but how can this be determined for a typical stack sample?

In nearly all cases, previous analyses of the stack sample will have reported the percent of water contained therein, as this is important for process control purposes. Given that information, one need only consult a table showing the saturation vapor pressure of water as a function of temperature, and the dew point is instantly determined.

Let us consider the examples of 10 percent and 20 percent water in the sample:

1. Refer to this table. Note that the spreadsheet is divided into six sections, separated by green bars. Each section provides vapor pressure data over a particular temperature range. All told, data is presented for temperatures from -10 deg C (14.0 deg F) to 114 deg C (237.2 deg F).

2. Assume that the gas sample in question is at atmospheric pressure—760 mmHg. By Dalton’s Law of Partial Pressures, 10 percent water would indicate a vapor pressure of 76 mmHg.

3. Take a look at the table. Although 76 mmHg does not appear, 75.7 does, and this is close enough. The corresponding temperature is 46 deg C (114.8 deg F), and that is the dew point of this sample.

4. For 20 percent water, a vapor pressure of 152 mmHg would be indicated. By reference to the table, the dew point is seen to be somewhere between 60 and 61 deg C (140-141.8 deg F). Prudence would dictate using the higher temperature as the operational dew point.

Interscan is here to help you with all application and technical issues. Feel free to contact us at any time.