GASD IS

Designed for Intrinsic Safety

Elevate Safety Standards with the GASD IS®: Purpose-Built for Explosive Atmospheres

Product Information

Portable Gas Detection Designed for Intrinsic Safety

Portable Gas Detector for Hazardous Locations (Certification Pending)

This portable gas analyzer is engineered to deliver laboratory-grade toxic gas measurement in environments where ignition risk must be controlled. Designed for use in hazardous (classified) areas and undergoing intrinsic safety certification, the instrument combines trace-level sensitivity with rugged field readiness, enabling reliable detection in refineries, chemical plants, confined spaces, and other potentially explosive atmospheres.

An integrated active sampling pump continuously draws air across the sensor for fast response and stable readings, while high-capacity rechargeable lithium-ion batteries provide a full shift of operation. Measurement data are presented on a clear digital display with live trend visualization, and onboard memory automatically records exposure history for documentation and compliance tracking. Configurable audible and visual alarms provide immediate warning when gas concentrations approach or exceed defined thresholds.

- Intrinsic Safety Architecture for Hazardous Environments: Designed in accordance with intrinsic safety principles defined in IEC 60079-11, the analyzer is intended for operation in flammable or explosive atmospheres without introducing an ignition source. Intrinsic safety certification is currently in finalization. This enables direct measurement at the point of risk rather than relying on remote sampling or indirect inference.

- Field-Ready Portability: A compact, impact-resistant enclosure and balanced handheld form factor support extended use in demanding field conditions. Long-duration battery operation minimizes downtime and supports continuous monitoring across an entire work period.

- System Connectivity and Integration: Standard analog and digital output options allow the analyzer to interface with plant safety systems, data loggers, and control platforms. This supports centralized monitoring, archival storage, and integration into existing EHS workflows.

- Rugged Industrial Construction: The enclosure is engineered for durability in harsh industrial settings, resisting vibration, dust, and temperature variation. The design prioritizes reliability in real-world environments where instruments are exposed to physical and environmental stress.

- Clear Data and Simple Operation: A high-contrast numeric display with live graphical feedback makes concentration trends easy to interpret in real time. Automatic data logging simplifies recordkeeping, exposure verification, and reporting, reducing administrative burden and supporting compliance documentation.

- Designed for Class I, Division 1 Groups A, B, C, and D hazardous locations (intrinsic safety certification pending)

- Designed to achieve Class I, Zone 0 AEx ia IIC T4 Ga (USA) protection level

- Designed to achieve Ex ia IIC T4 Ga (Canada) protection level

- Capability to detect 21 gases

- Portable

- Extremely low level sensitivity (gas dependent)

- Active and continuous sampling with an integral sample pump, powered by rechargeable Lithium-Ion batteries

- Digital readout of concentration, along with real time graphics display

- Data logging

- Audible and visual alarm

- Analog output (4-20 mA and 0-2.5 V)

- 8 hours of continuous service

| Intrinsic Safety (Certification Pending) | Class I, Division 1 Groups A, B, C and D, Intrinsically Safe (pending) |

| Class I, Zone 0 AEx ia IIC T4 Ga (USA) (pending) | |

| Ex ia IIC T4 Ga (Canada) (pending) | |

| Ambient Temperature Range: 32°F – 113°F (0°C – 45°C) | |

| T4 Temperature Classification is assumed at this time (pending) | |

| Accuracy | 5% |

| Display | Sunlight visible transflective LCD |

| Internal Battery | Rechargeable Lithium-Ion (5000 mAh) |

| Data Logging | Via integral SD card (32 GB) |

| Dimensions | 5½ in H x 8¼ in W x 10 in D (140 x 210 x 254 mm) Includes body and legs |

| Weight | 6.5 lb (2.95 kg) |

| Enclosure | Anodized aluminum |

| Power (when plugged in) | Universal AC outlet adapter. Rated voltage 100-240V, 50/60hz, USB A. Total output: 5V, 2400 mA or higher. |

| Calibration | Against standard gas mixture, or via Interscan’s SENSOR EXPRESS® |

GASES WE DETECT

Why Interscan Detectors

0-Downtime Sensor Replacement

Replacement Sensors On-Demand, Right When You Need Them

Extremely Low-Level Gas Sensitivity

Real Time Data Logging

INDUSTRIES WE SERVE

COMMON QUESTIONS

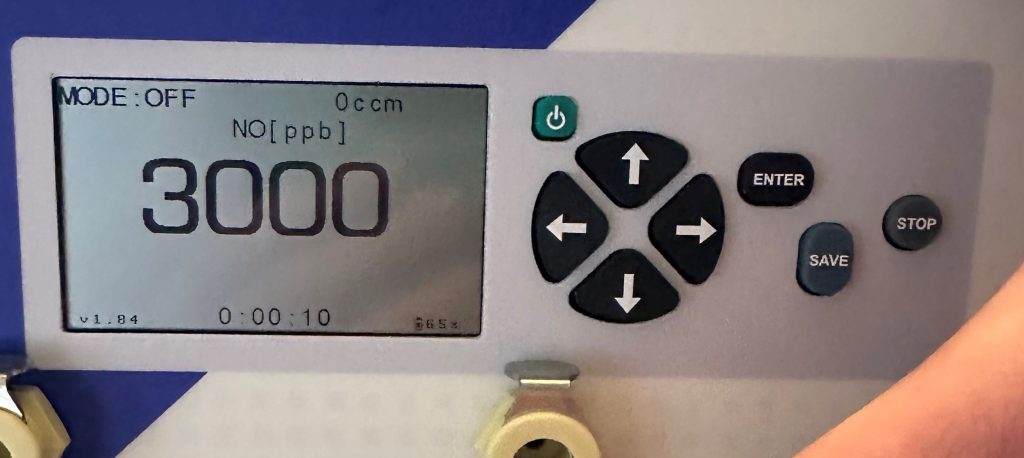

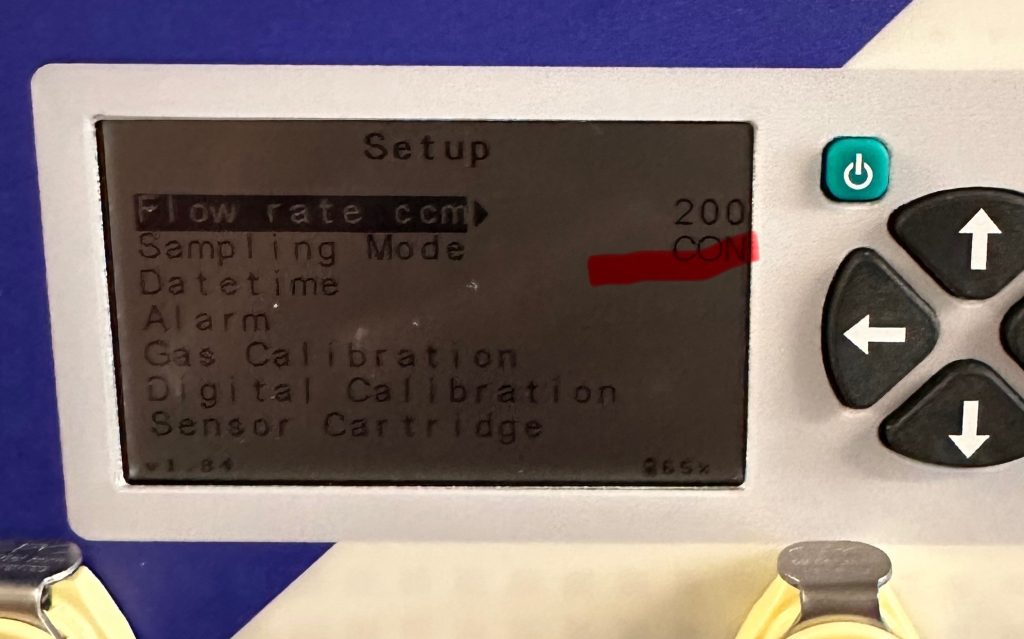

For accurate readings, the pump must be on while measuring. When you enter Measure-mode, the default is “Mode: Off “ (this means the pump is off) With measure mode “off”, it may appear like the instrument is measuring, but it is not measuring actually. (If the pump is off the display will read Mode: Off as shown below)

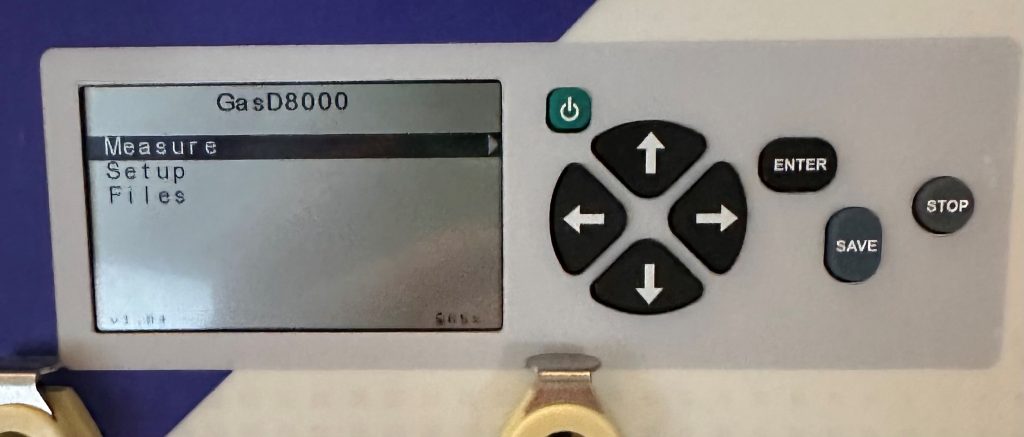

To turn the pump on, from main menu with MEASURE highlighted, press the Right Arrow and press Enter The display should read “Mode:On” and now your device is actively measuring. This is process should be used each time a measurement is taken. If pump was previously “off”, then once the pump is turned-on, the user can confirm that the instrument is measuring gas.

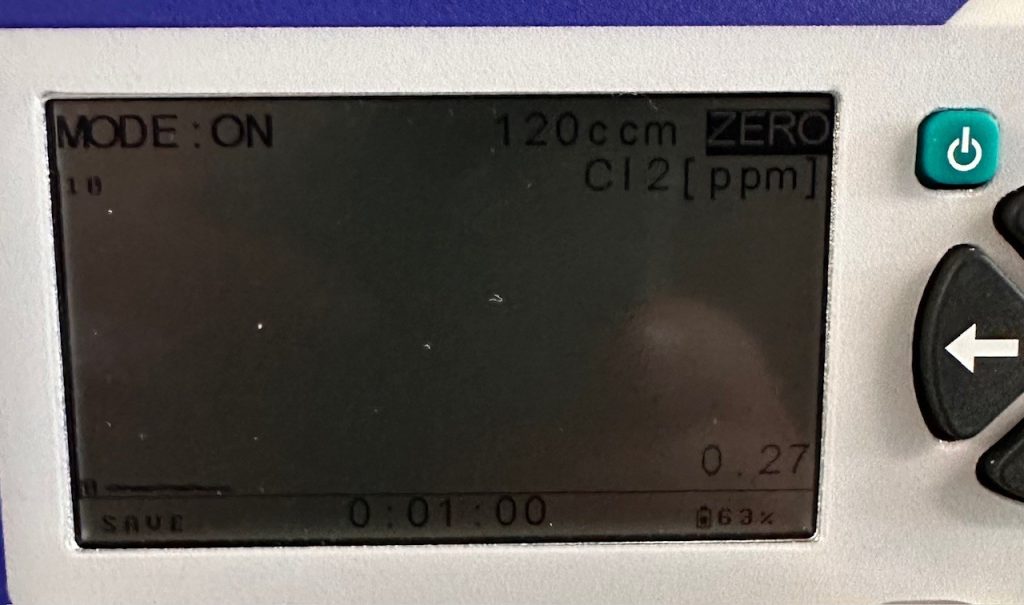

If the pump was turned on and the sampling mode is set to “CON” (See FAQs), but measurements are still reading Zero, it may be necessary to reset the zero on the device to restore measurement accuracy. (is possible that the zero was inadvertently reset while the instrument was stabilizing and thus measurement below that “new zero” will always read zero)

To reset zero : The instrument should be in an environment without any analytes, then power the instrument. Measure will be highlighted. Press the right-arrow and then press Enter. The instrument display should say “Mode:On”.

Let the instrument stabilize for 30 minutes.

After 30 minutes , press the up-arrow button to Highlight Zero and press Enter. This will establish a new zero for the instrument sensor.

Press the Stop button.

Expose instrument to the target gas to confirm the new zero is established and non-zero readings are present. (If your instrument is still reading zero, then please contact our technical support department)

If the sampling mode is not set to “CON”, press the down-arrow to highlight Sampling Mode, then press the right-arrow. Then use the up and down arrow to scroll to highlight CON

Power off the instrument.

Power the instrument back on. Measure will be highlighted. Press the right-arrow and then press Enter The device should be begin measurement