- The technological lifespan and sensor lifespan will determine if gas detectors are out-of-date.

- Sensor lifespan varies based on the type of sensor and its environmental conditions.

- Failure to calibrate, frequent malfunctions, inaccurate readings, and non-operational components indicate an outdated gas detector.

- Outdated gas detectors should be upgraded or replaced with new technology compliant with industry regulations.

Gas sensors are sensitive equipment, and even slight degradation of their function can be life-threatening. As gas detectors age, they can develop issues and give a false sense of security. Therefore, industrial hygienists and safety managers should know when a gas detection system is outdated. In this article, learn more about spotting malfunctioning gas detectors, their causes, and their standard lifespan.

Technological Life Span and Sensor Life Span

Gas detectors can go out of date because the technology and sensor lifespans have ended.

The lifespan of technology and sensors are related, but they are not interchangeable terms. Technology lifespan refers to the overall relevance and support for a particular equipment/device, while sensor lifespan refers to the durability and functionality of the sensors within that technology.

The features of each lifespan and the factors that influence them can differ and should be considered separately.

Technological Lifespan

The overall technological lifespan of a gas detection system can vary depending on the manufacturer, the quality of components, and how well it’s maintained. The technological lifespan of gas detectors can vary depending on several factors, and some key considerations are listed below:

Advancements in technology: Like many technological devices, gas detectors can become outdated as new technologies emerge. Advancements in sensor technology, signal processing, connectivity options, and data analysis techniques can improve detection accuracy, reliability, and functionality. Gas detectors that lack these advancements may be considered outdated compared to newer models.

Industry standards and regulations: Changes in industry standards and regulations can also impact the technological lifespan of gas detectors. New rules may require additional features or capabilities in gas detectors to ensure compliance with safety standards. Detectors that do not meet these updated requirements may become obsolete or less desirable in specific industries or applications.

Integration with other systems: Gas detectors are increasingly integrated with different safety and monitoring systems, such as building automation or industrial control setups. Detectors that are not compatible with these systems may be considered less technologically advanced than models offering seamless integration and interoperability.

Software updates and support: Manufacturers that provide regular updates and support for their products may extend the useful life of detectors by adding new features, improving performance, and addressing security vulnerabilities. Gas detectors that do not receive these software updates can put worker’s safety at risk.

Lifecycle management: Effective lifecycle management practices, including proactive maintenance, calibration, and component replacement, can help maximize the technological lifespan of gas detectors. Regular inspections and assessments of detectors can identify potential issues and opportunities for upgrades or replacements to ensure continued reliability and performance.

Staying informed about industry trends and advancements can help users make informed decisions about the timing of upgrades or replacements to ensure the continued effectiveness of gas detection systems.

Sensor Life Span

Gas sensors within the detection system have a finite lifespan, determined primarily by sensor type. Lifespan differences within a category depend on the brand, quality, and cost.

Hence, there is a wide variability of the guaranteed lifespan, and the following lifespans mentioned are only representative:

Electrochemical gas detectors: These detectors use electrodes and chemical reactions to detect gases such as carbon monoxide, nitrogen oxides, chlorine, hydrogen sulfide, etc., and typically have a lifespan of two to three years. However, sensors for hydrogen fluoride last only 12-18 months. Calibration and bump testing are the best ways to ensure they function well.

Catalytic Bead gas detectors: Catalytic bead detectors detect combustible gases such as methane or propane. They rely on the combustion of gases on a heated wire to produce a signal. The lifespan of catalytic bead sensors can vary but generally falls within the range of around five years.

Infrared gas detectors: Infrared (IR) gas detectors measure the absorption of infrared radiation by gases in the sample chamber. They are often used to detect gases such as methane, carbon dioxide, and hydrocarbons. IR detectors typically have longer lifespans of over five years than other sensors.

Photoionization detectors (PID): These detectors detect volatile organic compounds (VOCs) and other gases with high ionization potentials. They utilize ultraviolet (UV) light to ionize gas molecules, producing a measurable signal. The lifespan of PID sensors can vary but generally falls within the range of two to five years.

Solid-State sensors: Solid-state sensors, such as metal-oxide-semiconductor (MOS) sensors, detect hazardous gases that can be explosive when mixed with ambient air, like carbon monoxide, methane, ammonia, ethanol, and hydrogen. The lifespan of solid-state sensors typically lasts around two years.

Factors Affecting Sensor Lifespan

In addition to product design, the lifespan of sensors is also influenced by other factors listed here.

Environmental conditions: The gas detection system’s operating conditions can significantly impact the sensor lifespan. Exposure to extreme temperatures, high humidity, corrosive chemicals, or dust can accelerate sensor degradation. For example, a severe environment can cause shifts in baseline values and slower readings in electrochemical sensors.

Usage intensity: The frequency and duration of use can impact sensor lifespan. Sensors used continuously or in high-risk environments may degrade faster than those used intermittently or in less hazardous settings. Sensors may also degrade faster with frequent exposure to high concentrations of gases they are designed to detect. Physical stress, like extreme vibrations and shocks, will also spoil sensors.

Maintenance and calibration: Regular maintenance and calibration can help extend the lifespan of gas sensors by ensuring they operate within their designed parameters. Proper calibration can also help identify any early issues with sensor performance.

Manufacturer quality: The quality of the sensors and the overall gas detection system can also influence sensor lifespan. Higher-quality sensors and systems may have more durable components and better resistance to environmental factors, leading to longer lifespans.

Given these factors, users of gas detection systems need to monitor sensor performance and be aware of environmental conditions that may affect sensor lifespan.

How to Recognize Outdated Sensors

When sensors near the end of their lifespan, there are several signs that safety managers can look for. Some of the signs that the gas detection system may be outdated are:

Calibration failures: Calibration is crucial for ensuring the accuracy of gas detection readings. A system consistently failing to calibrate or maintain calibration suggests a fundamental problem with the equipment or its components.

High failure rate: If the system experiences frequent failures or malfunctions, it could be a key sign indicating an outdated gas detection system.

Unreliable readings: An outdated gas detection system may provide inaccurate readings or inconsistent performance.

Malfunctions or frequent false alarms: A system that experiences frequent malfunctions or false alarms is likely outdated or in need of repair.

Malfunctioning components: Displays, alarms, and other components are essential for conveying information to users and alerting them to potential hazards. If these components are malfunctioning or not functioning correctly, it undermines the effectiveness of the entire gas detection system.

Addressing these signs promptly is crucial for maintaining a safe working environment.

Steps to Take When the Gas-Detector is Out-of-date

When gas detectors are out of date, it’s essential to take action to ensure your facility’s continued safety and compliance. Here are the steps you can take:

Consultation: Consult with a qualified safety professional or vendor specializing in gas detection systems for expert advice based on your needs and requirements.

Upgrade or Replace: Depending on the assessment, upgrade or replace the outdated gas detection system with newer technology offering improved performance, reliability, and features. Replacement could involve replacing individual components such as sensors or control units.

Installation: To upgrade or replace the system, follow manufacturer guidelines and industry best practices to ensure optimal performance and reliability.

Testing and Calibration: Follow manufacturer recommendations and regulatory requirements for testing frequency and calibration procedures to ensure accurate and reliable performance.

Emergency Response: Review and update the facility’s procedures to incorporate the new gas detection system. Ensure that personnel know how to respond effectively to gas leaks or alarms.

Regular Maintenance: Implement a new gas detection system schedule to keep it in optimal condition. This includes cleaning, inspection, and preventive maintenance tasks, as the manufacturer recommends.

Following these steps can help industries transition from outdated gas detectors to newer, more reliable systems, ensuring facility and personnel safety.

Replacement of Gas Detectors

The timing of replacing outdated gas detectors can be due to three reasons:

Non-functional instruments: Gas detectors can be replaced when they malfunction. However, if safety managers wait until the equipment stops functioning to order and replace a new instrument, they risk gas detection and production downtime.

Manufacturer’s recommendations: Gas detectors can be replaced at fixed times based on manufacturers’ recommendations. Replacing sensors at pre-determined periods ensures that the gas detectors work unhindered for worker’s safety.

Regulatory Compliance: Depending on the industry and location, regulatory requirements may dictate the frequency of gas detection system replacement. It’s essential to stay informed about these regulations to ensure compliance.

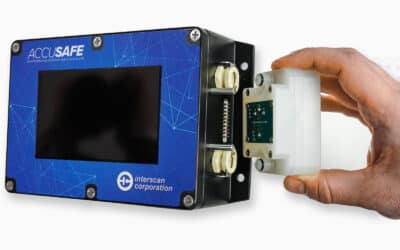

Interscan’s SensorExpress

Interscan, which produces fixed and portable gas detectors for 21 gases and vapors, offers the “Interscan SensorExpress” service, where sensors are replaced according to pre-determined schedules based on known sensor lifespan. The sensors are calibrated so that the new device can start functioning immediately after installation for the safety of personnel and facilities.

Written by:

Vijayalaxmi Kinhal

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

This article has been AI-assisted

Sources

Gautam, Y.K., Sharma, K., Tyagi, S., et al. (2021). Nanostructured metal oxide semiconductor-based sensors for greenhouse gas detection: progress and challenges. R. Soc. Open Sci. 8: 201324. https://doi.org/10.1098/rsos.201324

Isaac, N.A., Pikaar, I. & Biskos, G. (2022). Metal oxide semiconducting nanomaterials for air quality gas sensors: operating principles, performance, and synthesis techniques. Microchim Acta 189, 196. https://doi.org/10.1007/s00604-022-05254-0

Thompson, C. (2020, Feb, 25). Portable Gas Detection Maintenance. Retrieved from https://www.linkedin.com/pulse/portable-gas-detection-maintenance-craig-thompson.

Thurow, K., & Neubert, S. (2022). Innovative Sensor Technology for Emergency Detection in Life Science Laboratories. Studies in health technology and informatics, 291, 62–87. https://doi.org/10.3233/SHTI220008