- Employers can use the recommended hierarchy of controls to keep their employees safe from illness and injury in their facilities.

- Of the five strategies, elimination, substitution, and engineering controls are the most effective in controlling exposure since they do not require personnel intervention.

- Administrative controls and personal protective equipment are less effective in controlling risks as they require workers’ effort and are never used in isolation.

Safety managers and industrial hygienists use the hierarchy of controls to manage occupational hazards due to toxic and combustible gases in the workplace. It can reduce accidents and leaks that cause injury and illnesses. The hierarchy of controls provides structural guidelines to keep employees safe. In the US, the National Institute for Occupational Safety and Health has recommended and specified the five steps in the hierarchy of controls for workplace safety. Find out what these steps are in this article.

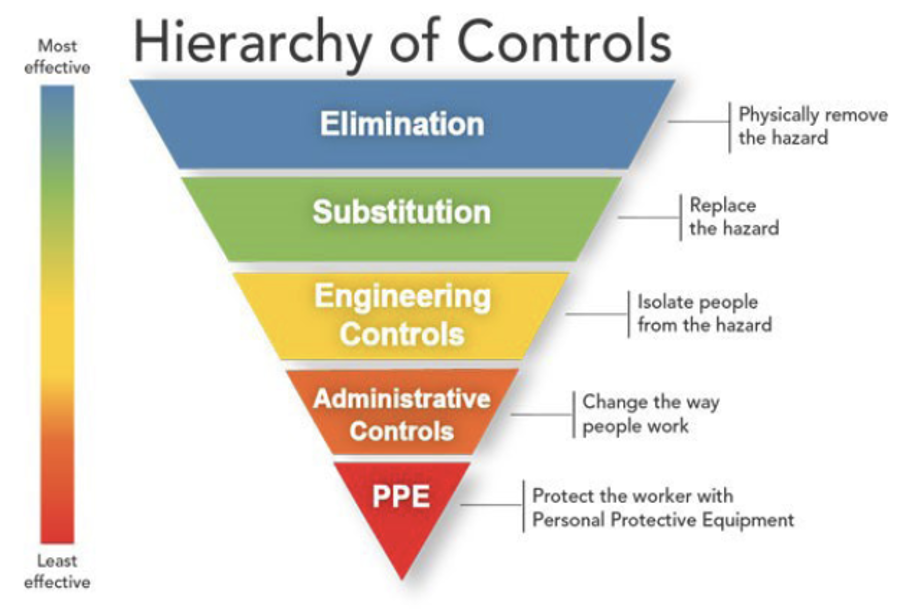

Figure 1: The hierarchy of controls recommended by NIOSH

What is the Hierarchy of Controls?

The hierarchy of controls is a method of “Prevention through design” (PtD) of occupational hazards. The process identifies and ranks safeguards to protect workers from hazards. The steps are arranged from the most effective at the top to the least effective at the bottom.

Safety managers and industrial hygienists in industries that use or produce toxic and ignitable gases will find that they must use a combination of steps to protect staff.

Industrialists can use the framework to design workplace hazards and risks from the planning and building stages of their operations. Preventing hazards is integrated into the workflow design and can affect several vital decisions. It can involve redesigning or retrofitting old establishments’ workplaces, procedures, and tools.

In the US, the National Institute for Occupational Safety and Health (NIOSH) recommends the hierarchy of controls in industries and facilities where workers regularly come into contact with hazardous gases and pollutants and are exposed to heavy machinery failure and accidents related to structures and vehicles. The Occupational Safety and Health Administration (OSHA) also supports using this hierarchy of controls.

The hierarchy of controls is an ideal order of actions to prevent and control hazardous exposures at the workplace. In order of preference, the steps are elimination, substitution, engineering controls, administrative controls, and PPEs, see Figure 1. These steps are discussed below.

-

Elimination

Elimination is the best option for removing a hazard so that there is no possibility of any exposure to workers. However, this step is the most challenging to implement. It may require significant changes and become expensive in established workplaces. Implementing in a facility in the planning or development stages is easier.

Some examples of gas exposure elimination can be the design or redesign of the production process to eliminate hazardous gases or equipment with the potential to leak.

-

Substitution

Substitution is the second best option among the controls. It involves replacing a hazardous substance or process with a safer alternative. It achieves a result similar to elimination and involves similar difficulties in implementation. Substitution reduces the risk of exposure to hazardous gases that can affect employees.

Examples of substitution are using a non-toxic chemical instead of caustic cleaning agents.

-

Engineering Controls

The third most effective strategy is engineering controls, designed to separate personnel from hazards. The ideal solution is to remove or reduce the risk at its source before workers contact it. The controls must limit or eliminate hazardous gas release on-site if there are gases. While engineering controls can be expensive to install, they typically have lower operating costs. To be effective, engineering controls should require minimal or no input or action by workers. These measures should not interfere with the typical workflow.

Examples of ways to limit exposure to gases are local exhaust ventilation fans and ventilated storage spaces to reduce gas concentrations. Using fixed gas sensors is also a standard engineering strategy to monitor and control through quick detection and identification of leak sources.

-

Administrative controls

Administrative controls are the fourth most effective control strategy. Employers can change how staff work and perform tasks. This requires engagement with staff, and its effectiveness depends on personnel’s compliance. It is not used in isolation but along with other control strategies. It is low-cost and favored by employers but is less effective.

For example, employers can limit time spent in places with potentially hazardous gases and label containers to reduce exposure to gases. Employers have posters that provide detailed information on the dangers of gases, safe operating procedures, and emergency evacuation plans and routes. Install audio and visual alarms to inform and warn staff of an emergency.

-

Personal Protective Equipment

Personal protective equipment (PPE) is the last defense against occupational hazards. The equipment worn or used by employees while working is the least effective stage. PPE is never used in isolation but in combination with other strategies. This strategy is used in the following cases:

- When other controls are being developed

- Other controls cannot eliminate or reduce hazard exposures

- It is the only option available

The effectiveness depends on quality, condition, regular monitoring, maintenance, proper usage, and regular training and drills. PPE choice will depend on hazard assessment.

To reduce gas exposure, depending on the chemicals and workplace, PPE can include goggles and masks for eye and face protection, gloves for hand and arm protection, hazmat suits for full-body protection, respirators, etc.

Both administrative and PPE control strategies require effort by supervisors and staff.

Using the Hierarchy of Controls

The Hierarchy of Controls is a guideline for employers. It is up to the employer to apply them to improve worker safety effectively. Some of the steps advised by OSHA in applying the Hierarchy of Controls are listed below:

- Identify the potential hazards which must be controlled.

- Find ways of applying the five suggested strategies by brainstorming, talking to workers, and consulting with experts.

- Consider the pros and cons of each alternative option.

- Check if the measures are feasible for your facility:

-

- Is it appropriate for your facility’s gases and the resulting risks and illnesses?

- Do the measures meet compliance requirements?

- Are the alternatives available and cost-effective?

- Does it add to workers’ burden?

- Choose options higher in the hierarchy through consultation with workers and their representatives.

- Combining methods, including engineering and administrative controls and PPE, provides maximum protection.

- Conduct trials of newly chosen strategies and alternatives.

Employers should try to ensure the measures being implemented are higher in the hierarchy to remove and reduce worker exposure to gases. They should also constantly review their measures, stay up-to-date with safety issues in their industry, and take advantage of any new technology that can keep their workers safe.

Gas Detectors

Gas detectors are crucial equipment since various industries use or produce gases. Fixed gas detectors require no worker intervention and operate around the clock, while portable devices can be carried to places with heightened risks, like confined spaces or emergency response measures. The choice of the correct sensor, number, and placement of sensors must also be well planned to provide effective and quick leak detection to alert staff. Interscan offers fixed and portable gas detectors for over twenty gases in various concentration ranges.

Learn more about how our gas detectors can help keep your workers safe.

Sources

CDC. (2024, Apr 10). Hierarchy of Controls. Retrieved from https://www.cdc.gov/niosh/hierarchy-of-controls/about/index.html

Deziel, N. C., McKenzie, L. M., Casey, J. A., McKone, T. E., Johnston, J. E., Gonzalez, D. J., … & Morello-Frosch, R. (2022). Applying the hierarchy of controls to oil and gas development. Environmental research letters: ERL [Web site], 17(7).

OSHA. (n.d.). Identifying Hazard Control Options: The Hierarchy of Controls. Retrieved from

https://www.osha.gov/sites/default/files/Hierarchy_of_Controls_02.01.23_form_508_2.pdf