- Ozone is used both as a gas and a liquid for disinfection, sanitization, and oxidation purposes.

- It can be produced as a secondary pollutant through various industrial processes.

- Ozone must be monitored, as it poses a health risk, and its corrosive and reactive properties make it hazardous to facilities, equipment, and materials.

While stratospheric ozone is beneficial for the environment and human health, it can be harmful when it comes into contact with people. It produces several health problems, especially for vulnerable groups. Ground-level ozone is also an occupational hazard in several industries. This article identifies 15 sectors that require ozone detection to ensure worker safety. Find out if your industry is one of them. The industries are grouped into two categories: those that produce it as a byproduct of chemical interactions and those that use it for production or purification.

Industries Using Ozone

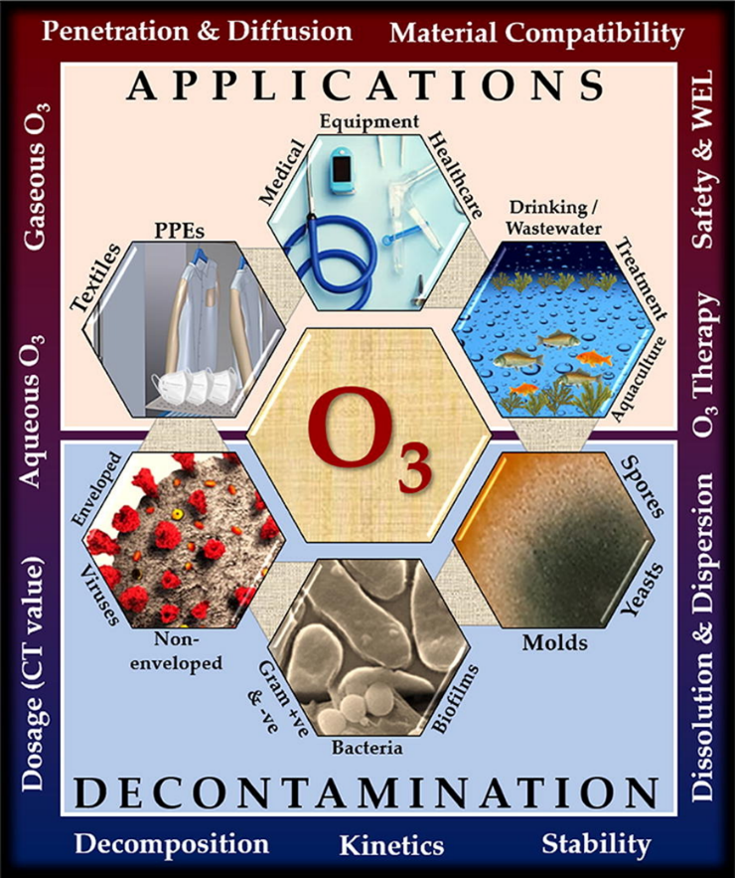

Ozone is a colorless to bluish gas that can condense into a dark blue liquid or crystals. At concentrations below two ppm, it has a characteristic odor. It is used as a disinfectant, antimicrobial agent, catalyst, and oxidizer, among other applications, as shown in Figure 1. The industries using ozone as an agent are discussed below.

Figure 1: Industrial applications of ozone, Epelle et al. 2023. (Image credits: https://doi.org/10.1016/j.cej.2022.140188)

-

Wastewater and Water Treatment

Ozone is used to purify drinking water and treat the high levels of organic matter and contaminants in wastewater. Ozone oxidizes pollutants as well as inorganic compounds like iron, manganese, nitrate, and hydrogen sulfides to improve taste and odor. Ozone also inactivates viruses, protozoa, and bacteria found in wastewater treatment, but has to be supplied at higher concentrations. As water becomes increasingly scarce, more wastewater will be recycled, and the use of ozone is expected to increase in this industry in the future.

Ozone risks: Ozone is corrosive and reactive and must be used with stainless steel materials. Off-gases must be monitored and properly disposed of to prevent harm to workers.

-

Semiconductor Manufacturing

Ozone is used in manufacturing semiconductors for oxidation processes and wafer cleaning. Precise ozone detection is essential for decontaminating chip surfaces and optimizing silicon film quality for process control, as well as for maintaining a safe working environment. The semiconductor industry is driving demand for ozone detectors.

Ozone risks: Ozone emissions during atomic layer deposition (ALD) processes must be monitored to prevent worker exposure, which can lead to health issues. Ozone misuse can damage electronics as it oxidizes several materials, changing their properties and efficiency. Also, ozone contamination of process water can affect water quality.

-

Healthcare Sector

Ozone is one of the few disinfectants that is effective in air and water. It is used to decontaminate personal protective equipment (PPE), surfaces, equipment, devices, materials, and the air, thereby controlling the spread of infectious diseases in healthcare organizations. Ozone gas can decontaminate hard-to-reach areas and is effective against several microbes. It was widely used during the COVID pandemic as it decomposes rapidly into environmentally friendly oxygen.

Ozone risks: The reaction of ozone with organic matter is influenced by several factors, including temperature, relative humidity, pH, the nature of the microbe, ozone generation method, exposure dosage, and duration. Factors that affect the process will also impact ozone stability and carry the risk of workers inhaling the gas. Therefore, staff should always use personal protective equipment (PPE), and the gas levels in the air must be regularly monitored. Fixed and portable ozone detectors are necessary for the sector.

-

Paper and Pulp Industry

Ozone is produced from oxygen. After being used as an oxidant, it is converted back to oxygen. It reacts in seconds to minutes with many substances involved in pulp and paper making, such as recycled and virgin fibers, sludge, process water, and wastewater treatment. It is also a bleaching agent and is used to bleach 8% of the global pulp.

Ozone risks: The gas is used at high concentrations to bleach pulp and paper, so its levels in the air must be monitored to protect workers.

-

Automotive Industry

Ozone is used mainly for testing and selecting durable materials and components. Ozone’s reactivity and non-specific oxidative properties are leveraged to test material aging and deterioration. Samples of materials are kept in an ozone atmosphere for days or weeks, depending on the material and purpose, to observe the physical, chemical, and visual changes that can occur under ambient conditions. Ozone is also used for cleaning and sterilizing cars to remove mold and spores, leaving no chemical residues or odor.

Ozone risks: When ozone is used for cleaning cars in automotive facilities or car washes, a spot check is necessary to ensure the health of personnel and customers, as high concentrations of the gas are often employed. Fixed gas analyzers are helpful for this purpose.

-

Food and Beverage Industry

Ozone is used as an alternative to chemical methods to reduce microbial contamination in the food and beverage industry, as it can be generated onsite, does not leave chemical residues or cause antimicrobial resistance, has a short shelf life, and is environmentally friendly. It is used to sterilize air and surfaces in food and beverage preparation, for odor removal, and in the processing of vegetables, fruits, meat, and seafood. Ozone is used in its gaseous and aqueous forms.

Ozone risks: The ozone concentrations necessary for disinfection are above permitted levels, so the levels must be controlled at several points and areas, such as gas generation, equipment and surface disinfection, bottling, and wastewater treatments to ensure that only the required amounts of gas are used to protect personnel health and for compliance.

-

Pharmaceutical Industry

Ozone is a standard cleaning and sterilization agent in pharmaceutical manufacturing to remove microbes and contaminants. It is used to disinfect the environment, the finished product, and the surface. It is used both as a gas and in dissolved form, where the gas is added to pure water used for cleaning purposes. Ozone detection is used to ensure worker safety, quality, and process control.

Ozone risks: Dissolved ozone as a sanitizer is a new method that lacks standardization, and mixing has its pitfalls. Hence, more gas can be added than necessary, which does not dissolve in water and escapes into the air. Also, ozone can outgas from the water. Therefore, the gas must be monitored at residual, postdestruct, and end-loop valves.

-

Aquaculture and Fisheries

Ozone’s oxidant properties are utilized in water purification to enhance water quality and hygiene by removing odors and colors, as well as reducing pathogen numbers, in aquaculture and fisheries. Ozone is used during the pretreatment of incoming water that holds stock for quality control and effluent treatment. It is also used to treat microbial infections in fish embryos, eggs, and larvae, as well as juvenile and adult fish.

Ozone risks: Ozone can be an irritant to fish, causing mortality, lower hatching rates and growth, damaged tissue, behavioral abnormalities, and physiological changes in aquatic stocks when used in high doses. So, safe and optimal levels must be established for each species and ontogeny and maintained on the farms through gas monitoring and maintenance of optimal temperature and water salinity.

-

Laundry and Textile Industry

Ozone is used as an oxidative agent for bleaching, desizing, dyeing, surface modification, color stripping, stone-washing denim, clearing, and wastewater treatment. As a wastewater treatment, it removes organic matter, dyes, and other pollutants. In the laundry industry, it is used to sanitize and disinfect clothes. Ozone is favored because it can act at room temperature in neutral, acidic, and alkaline conditions, reducing water, energy, and chemical consumption, as well as waste production.

Ozone risks: It is crucial to measure the ozone produced by the generator to prevent the production of excess gas, enhance process efficiency, and minimize occupational hazards. Overuse of ozone can lead to significant loss of textile strength, corrosion of metal components except stainless steel, damage to plastics in finishing machines, and its flammable nature. So, regular monitoring and alarm systems are necessary.

-

Hydraulic Fracking

Significant amounts of water are necessary for fracking to release natural gas. Millions of liters of water are contaminated by chemicals added to the water and by salts, metals, and radioactive material picked up underground. Ozone is used to treat contaminated water, reducing the presence of chemicals and salts, thereby recycling it and increasing access to water for local communities.

Ozone risks: Ozone levels must be monitored at generation points and areas to prevent excessive exposure of workers onsite.

-

Mining

Ozone is also used to treat wastewater generated during mineral processing, slurry transportation, and dust suppression. Ozone reacts with and reduces salts and organic matter in sewage, enabling the recycling of water in mining.

Ozone risks: Ozone levels must be monitored at generation sites to ensure the safety and health of staff.

-

Chemical Manufacturing

Ozone is used in the chemical reactions and processes involved in the manufacture of various products, including deodorants and specialty chemicals such as adipic acid, which is used to produce nylon.

Ozone risks: Gas detection is necessary to ensure the correct amount of ozone is used, maintain process efficiency, and ensure worker safety and health.

Industries Producing Ozone

Some industries produce ozone directly or indirectly. Indirectly, ozone is created as a secondary pollutant because nitrogen oxides (NOx) and volatile organic compounds (VOCs) react with sunlight.

-

Oil and Gas

Oil and gas operations, including pre-production and production activities, particularly hydraulic fracturing, account for 37% of global VOCs and 26% of NOx emissions. These react with sunlight to produce ozone, which has become an environmental concern for neighboring communities and has led to unrest.

Ozone risks: The onsite creation of ozone can also pose a problem for workers, and gas levels must be monitored through ozone detectors to ensure compliance and worker safety.

-

Fertilizers and Agriculture

Nitrate fertilizer production processes release NOX that indirectly forms ozone in the air. It can also be used for sanitization in some processes. Additionally, only 30-50% of the fertilizers applied to the soil are utilized. The rest seeps into the soil or is released into the air as NOx compounds, which produce ozone and become an environmental pollutant.

Ozone risks: The secondary production of ozone in fertilizer manufacturing facilities must be monitored for personnel safety and compliance.

-

Aerospace

Ozone in the stratosphere can enter airplanes through their air-conditioning systems, causing symptoms associated with jet lag and air sickness, including fatigue, headaches, respiratory system irritation, coughing, and chest pains. Flight levels above 27,000 feet are susceptible to ozone.

Ozone risks: Maintain ozone levels in the cabin by using ozone monitors and decomposers to ensure the health of cabin crew and passengers, as well as maintain the durability and integrity of materials and safety components that could be oxidized by ozone.

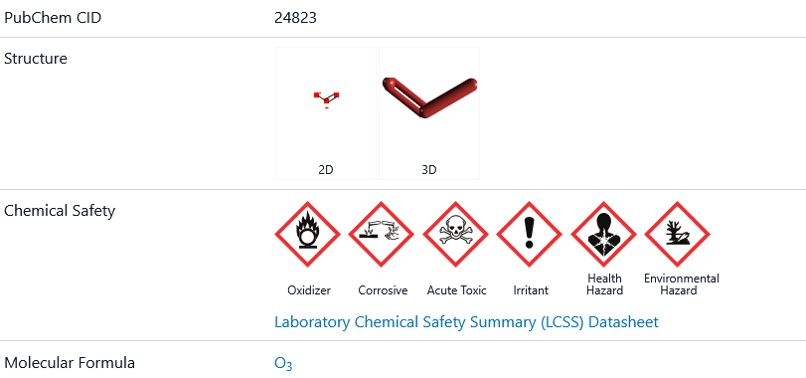

Figure 2: Compound summary of ozone by Pubchem. (Image credits: https://pubchem.ncbi.nlm.nih.gov/compound/Ozone)

Why Ozone Detection is Necessary

As awareness of ozone occupational hazards grows (see Figure 2), government regulations worldwide are becoming stricter, making it mandatory to maintain ozone levels below permitted levels to prevent workers’ exposure to the gas.

Analyzers accurately detect ozone to monitor its concentration in the atmosphere and alert management to high concentrations, enabling them to initiate control actions or evacuations as necessary. The demand for ozone detectors is significant, and the market worth $116 million in 2025 is expected to rise by 6.8% between 2025 and 2033. North America and Europe are the leading regions in demand, followed by the Asia-Pacific region.

Interscan offers the advantages that industries seek in ozone detection, including precision, reliability, miniaturization for portable devices, and compatibility with IoT (Internet of Things) and data analytics for real-time monitoring. The company offers both fixed and portable gas analyzers to provide comprehensive ozone detection and tracking for the industries.

Discover more about Interscan ozone detectors tailored for your industry.

Sources

Ahmedabad Textile Industry’s Research Association. (2023, June 12). Ozone: Revolutionizing Textile Processing for a Greener Future. Retrieved from https://atira.in/ozone-revolutionizing-textile-processing-for-a-greener-future/

Blonshine, T. (2006, April 2). Dissolved Ozone in Pharmaceutical Water Systems: How and Where to Measure Dissolved Ozone. Retrieved from https://www.pharmtech.com/view/dissolved-ozone-pharmaceutical-water-systems-how-and-where-measure-dissolved-ozone

Bullis, K. ( 2012, August 1). Using Ozone to Clean Up Fracking. Retrieved from https://www.technologyreview.com/2012/08/01/184685/using-ozone-to-clean-up-fracking/

Cable, J. (2011 April). How Ozone Affects Passengers & System Components. Retrieved from https://www.duncanaviation.aero/intelligence/how-ozone-affects-passengers-system-components

DiMarket. (2025, March 15). Future Forecasts for Ozone Gas Concentration Detectors Industry Growth. Retrieved from https://www.datainsightsmarket.com/reports/ozone-gas-concentration-detectors-39463#summary

EPA. (1999). Wastewater Technology Fact Sheet Ozone Disinfection. https://www3.epa.gov/npdes/pubs/ozon.pdf

EPA. (2025, March 11). Ground-level ozone basics. Retrieved from https://www.epa.gov/ground-level-ozone-pollution/ground-level-ozone-basics#

Epelle, E. I., Macfarlane, A., Cusack, M., Burns, A., Okolie, J. A., Mackay, W., … & Yaseen, M. (2023). Ozone application in different industries: A review of recent developments. Chemical Engineering Journal, 454, 140188.

Epelle, E. I., Macfarlane, A., Cusack, M., Burns, A., Okolie, J. A., Vichare, P., … & Yaseen, M. (2023). Ozone decontamination of medical and nonmedical devices: an assessment of design and implementation considerations. Industrial & Engineering Chemistry Research, 62(10), 4191-4209.

Fortune Business Insights. (n.d.). Machinery & Equipment/Ozone Analyzer Market. Retrieved from https://www.fortunebusinessinsights.com/ozone-analyzer-market-106682

Hamid, Z., Meyrick, B. K., Macleod, J., Heath, E. A., & Blaxland, J. (2024). The application of ozone within the food industry, mode of action, current and future applications, and regulatory compliance. Letters in Applied Microbiology, 77(11), ovae101.

Hostachy, J. C., van Wyk, B., & Metais, A. (2014). The use of ozone in the pulp and paper industry. PaperASia, 30, 22-28.

Jenkins, S. (2018., October 25). The Use of Ozone in Chemical Process Industries (CPI) Applications. Retrieved from https://www.chemengonline.com/the-use-of-ozone-in-chemical-process-industries-cpi-applications/

Körlü, A. (2019). Use of Ozone in the Textile Industry. IntechOpen. doi: 10.5772/intechopen.81774

Leathwood, H. (2022, August 22). Fracking is the #1 cause of dangerous ground-level ozone. Retrieved from https://350colorado.org/fracking-is-the-1-cause-of-dangerous-ground-level-ozone/

Lovino, V., Riglietti, A., Tolomeo, A., Capasso, G., Di Vittorio, M., Brattoli, S., Tesse, G., Dimiccoli, V., Spartà, M., & Perioli, L. (2025). Use of Ozone for Disinfection of PHARMODUCT® Automatic System for Antineoplastic Compounding. Pharmaceuticals, 18(2), 140. https://doi.org/10.3390/ph18020140

Parbha, V., Barma, R. D., Singh, R. & Madan, A. (2015). Ozone technology in food processing: A review. Trends in Biosciences, 8(16), 4031-4047.

Powell, A., & Scolding, J. W. (2018). Direct application of ozone in aquaculture systems. Reviews in Aquaculture, 10(2), 424-438.

Pubchem. (n.d.). Compound summary of ozone. Retrieved from https://pubchem.ncbi.nlm.nih.gov/compound/Ozone

Xu, M., Tian, X., Lin, Y., Xu, Y., & Tao, J. (2024). Design and Performance Evaluation of a Deep Ultraviolet LED-Based Ozone Sensor for Semiconductor Industry Applications. Micromachines, 15(4), 476. https://doi.org/10.3390/mi15040476