- Personal protective equipment (PPE) should be the last line of defense used to minimize the risks of occupational hazards.

- Employers will need a PPE program to identify, choose, and provide risk-appropriate equipment and train staff in its use.

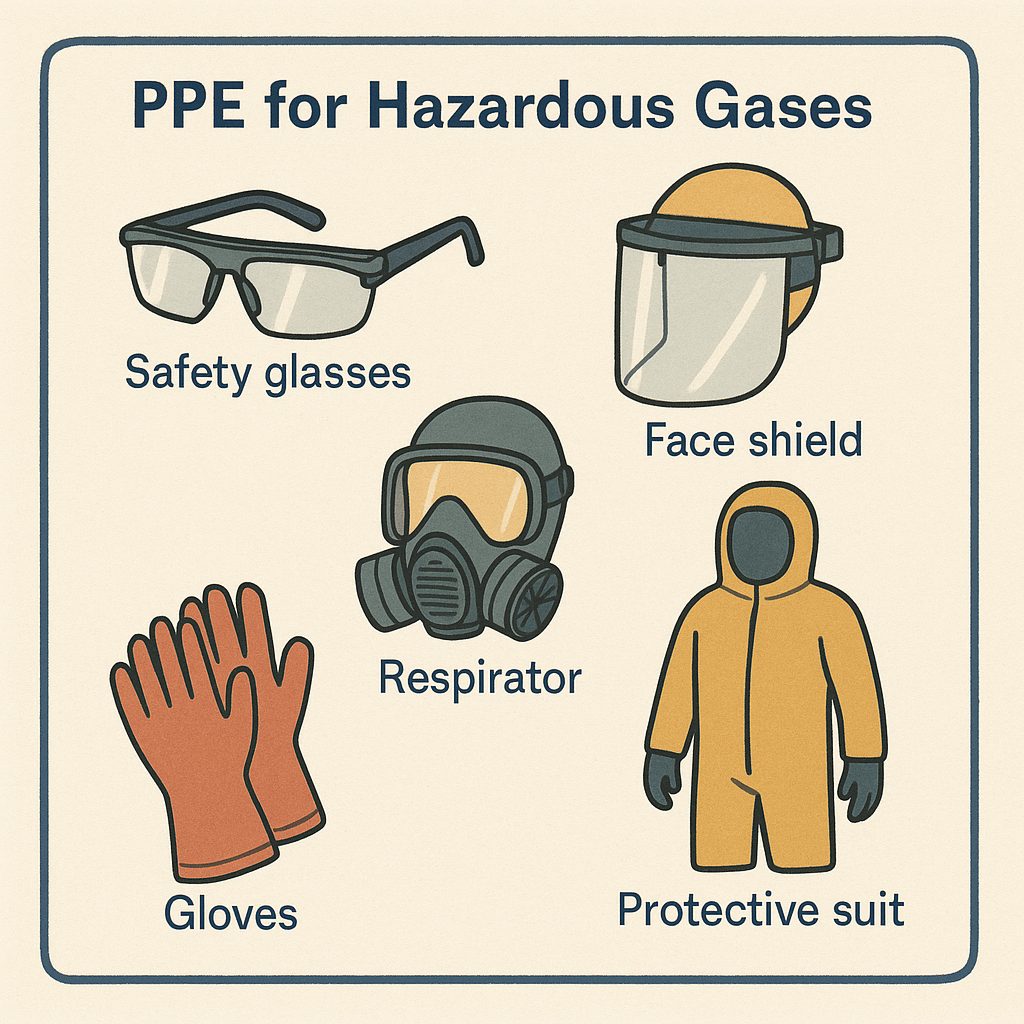

- The PPE that minimizes hazardous gas risks includes face, eye, arm, hand, foot, and respiratory protection, as well as emergency equipment.

Employers are required to provide a safe and healthy workplace for their staff. Exposure to occupational hazards must be eliminated or limited as much as possible. Personal protective equipment is one of the controls that employers can use for this purpose. In this article, you will find out what personal protective equipment is used to limit exposure to hazardous gases.

What is PPE?

Personal protective equipment (PPE) is used in industries to limit exposure to hazards that exist in the workplace.

Various hazards, such as chemical, physical, and biological hazards, can affect workers’ safety and health in workplaces.

The hierarchy of controls suggested by the National Institute for Occupational Safety and Health (NIOSH) considers PPE the fifth and last line of defense to prevent occupational illness, injuries, and fatalities. PPEs are necessary when all the other controls cannot eliminate risks to workers. Industries usually use them with different controls, such as engineering and administrative controls, as removing all hazard risks, including those from toxic and explosive gases, is generally impossible. PPEs should not be the first means of controlling the dangers of hazardous gas exposures.

PPE is mandated for industry by various Occupational Safety and Health Administration (OSHA) standards in the USA. OSHA 1910.132 outlines the general employer’s responsibility and the need for PPE requirements. These standards require that all PPE is appropriate for the hazards, made from a safe design, fits correctly, and is provided by employers.

Employers should have a “Personal Protective Equipment Program” to protect workers adequately. Using PPE also helps owners comply with regulatory requirements and improves productivity and efficiency, as people can focus on their work confidently without fear of exposure effects.

PPE for Hazardous Gases

The PPE requirements will vary depending on the hazards found in a workplace. Hazardous gases pose a danger to workers through breathing in toxic gases and contact with the skin and eyes. Flammable and explosive gases usually require evacuation for all staff. Any staff dealing with fire needs special PPE.

The types of PPE used against hazardous gases are eye, face, hand, respiratory, and full body protection. The various equipment needed is discussed below.

Eye and Face Head Protection

For eye and face protection against gases, safety glasses, goggles, and face shields are recommended.

- Eye protection: Goggles and safety glasses shield eyes from gases and chemical splashes. These can also be useful against dust, debris, and impact. The PPE must have a comprehensive seal around the eyes to prevent contact with hazards from any angle. The glasses and goggles can have anti-fog and anti-scratch coatings to improve visibility and durability.

- Face shields: Face shields can protect the entire face, nose, and eyes from gases and chemicals. These also offer protection against flames, heat, and debris. The shield must have a clean and transparent visor for good visibility. Face shields are necessary when handling chemicals, during cleaning, and during maintenance.

Respiratory Protection

Several gases, fumes, and vapors can cause severe health effects when even small quantities are inhaled acutely or chronically. Hence, respiratory protection is a chief means of protecting workers from hazardous gases. Masks and respirators are used depending on the protection levels needed.

- Disposable masks: Surgical or N95 respirators are light and can filter out 95% of airborne particles. Therefore, they protect against dust, fibers, smoke, and microbes. Industries producing asbestos, insulation wool, or clothing can use them. However, they are not effective against gases or chemical fumes.

- Respirators: Half-face and full-face respirators are needed when more effective protection is required, as in the case of hazardous gases and chemical fumes. These are used in various industries, including the gas and oil sectors. Half-face respirators cover the nose and mouth, and full-face respirators cover the entire face and eyes. The respirators are equipped with filters customized to specific contaminants.

Hand, Arm, and Foot Protection

Workers’ arms, hands, and feet can come in contact with gases. Gloves and arm guards can prevent skin contact in these cases.

- Gloves: Chemical-resistant gloves are a common hand protection made of varying materials, such as nitrile or latex. Nitrile gloves are resistant to chemicals and useful when people handle containers during storage, transport, or work processes. The gloves’ materials must be chosen carefully, as they have different properties and offer protection against varying chemicals. Gloves must be a snug fit and not interfere with dexterity or protection.

- Arm guards: Arm guards provide coverage up to the forearm and protect against gases and chemical splashes. Like gloves, arm guards are made of different materials and offer varying protection.

- Chemically resistant boots: PPE for boots and shoes must be slip-resistant in case of spills and chemical-resistant to protect feet. The sole must be maintained in good condition to avoid leakage.

Body Protection

Complete body protection is necessary in cases where workers must be protected from fires, heat, toxic chemicals, or electric hazards.

- Flame-resistant clothing: Workers will need special flame-resistant clothing for the entire body to protect against fire and heat risks. These clothes have fire-retardant properties and safeguard people against burns for a short time, allowing them time to escape. The material is also moisture-wicking and can keep people dry and cool.

- Coveralls are one-piece protective outfits that shield the body from chemicals and dust. These are made of cotton, polyester, or special materials. The overalls can have pockets to carry tools and are meant for daily use in industries like the oil and gas industry.

Emergency equipment

Only a few chosen, trained staff members are allowed to handle emergencies such as gas leaks, fires, or explosions. They need eye, hearing, and full-body protection with full-face respirators. These “full face-piece self-contained breathing apparatus (SCBA)” must have compressed air cylinders, as the environment might contain poisonous gases. Hearing protection includes earplugs and earmuffs.

Personal Protective Equipment Program

The employer must initiate the Personal Protective Equipment Program, but the staff’s cooperation and engagement are essential for it to succeed.

Employer responsibilities

According to OSHA, the employers’ responsibilities in the PPE Program are as follows:

Assessment: Employers must assess their facilities to identify the chemicals they use and the hazardous gases produced during reactions or processes. They must also acquaint themselves with the safety and health effects of dangerous gases to identify risks. Some can be toxic and cause illness and fatalities, while others can be explosive. Some will be both unhealthy and flammable.

Appropriate PPE: After identifying the risks from hazardous gases, employers and safety managers must determine the proper protection and PPE necessary. Care must be taken to ensure that the PPE is well designed to properly fit workers of all sizes and genders and provide adequate security.

The US Environmental Protection Agency (EPA) recognizes four levels of protection and prescribes suitable PPE.

- Level A protection meets the challenges of the highest degree of danger and body exposure to hazards and emergencies. It involves using chemical-resistant gloves, boots, and entire-body protection with SCBA.

- Level B protection involves the highest defense for the respiratory organs, not the skin. SCBA, face shield, chemical-resistant gloves, clothing, and boots are needed.

- Level C protection uses PPE for known levels of gases in the air. It includes full-face purifying respirators, chemical-resistant gloves, boots, masks, and hats.

- Level D protection is used when no known contaminants are present, including gloves, coveralls, safety glasses, face shields, and chemical-resistant boots.

For more information, consult the EPA resource.

Train and implement: It will be necessary to inform and train the workers on using PPE and its limitations. Training programs should advise the staff of the following themes:

- When PPE use is necessary

- Which PPE to use

- How to put on, wear, and take off PPE

- Care, maintenance, disposal, and replacement of PPE

Providing PPE may not be enough. Workers must be informed of the dangers of hazardous gases that PPE will reduce and must motivate staff to wear PPE, even if they are cumbersome. The employer must ensure that each worker understands the use of PPE or is provided with additional training.

Maintenance: Proper maintenance can extend the lifetime of the PPE. Over time and through repeated use, PPEs can get worn out or damaged and must be replaced.

Employers should regularly review, evaluate, and update the effectiveness of the PPE program by incorporating new information on risks and PPE innovations.

Employees responsibility

PPE can’t protect workers if they do not use the equipment correctly. To ensure their health, each employee must comply with the following points:

- Understand need: Attend and understand the information given in the training sessions on risks that PPE can minimize and the appropriate choice and use of PPE.

- Use PPE: The required PPE must be worn each time the worker performs a risky job or goes into high-risk areas as prescribed. They should also clean and maintain their PPE, as it is meant to keep them safe.

- Report damage: Workers should inform supervisors and managers of any damage or loss of function in their PPE so that it can be replaced in time.

Each type of PPE must meet specific requirements and standards set by OSHA, available in 29 CFR. US industrialists can consult this resource for more information on PPE specifications to comply with regulations.

Integrating PPE With Other Controls

PPEs are rarely used alone but in combination with other controls. Gas analyzers are one of the standard engineering controls used where hazardous chemical vapors exist. Fixed gas detection systems monitor the air around the clock to provide early warning of higher-than-permitted levels of dangerous gases. The gas readings can guide the choice of PPE by deciding the level of protection needed in a facility. Interscan offers AccuSafe, which can detect over 20 industrial hazardous gases for monitoring and timely warnings.

Contact us at Interscan to learn more about our gas analyzers to keep your facility safe and healthy.

Sources

Arizona Department of Administration, Risk Management Division.gov (2023 Feb). Personal protective equipment. Retrieved from https://staterisk.az.gov › default › files › 2023-02

Burge, S. (2025, Jan 1). Essential Personal Protective Equipment List. Retrieved from https://internationalfireandsafetyjournal.com/personal-protective-equipment-list/

EPA. (2024, Sept 30). Personal Protective Equipment. Retrieved from https://www.epa.gov/emergency-response/personal-protective-equipment

HSE. (n.d.). Using personal protective equipment (PPE) to control risks at work. Retrieved from https://www.hse.gov.uk/ppe/managing-risk-using-ppe.htm

OSHA. (2023). Personal Protective Equipment. Retrieved from https://www.osha.gov/sites/default/files/publications/osha3151.pdf

Tarlengo J. (2025, Mar 28). Everything You Need to Know About PPE Safety. Retrieved from https://safetyculture.com/topics/ppe-safety/