- Industries are now going beyond minor injuries and illness reduction to eliminate serious injuries and fatalities (SIF) events and rates.

- Several research findings show that employers and management, not workers, have a significant role in preventing SIF incidents.

- An organizational-level approach that uses engineering measures based on the hierarchy of controls is the most effective in reducing the SIF rate.

Industrial safety is usually focused on reducing frequent and minor accidents. Serious injuries and fatalities (SIF) are overlooked since their occurrence is seldom. However, annually, SIF accounts for 380,000 deaths worldwide. Measures to prevent minor incidents have been proven not to eliminate SIF. Industrial hygienists and safety managers must focus on specific control measures to decrease SIF rates. This article introduces some basic approaches used to decrease SIF rates.

Severe Injuries and Fatalities

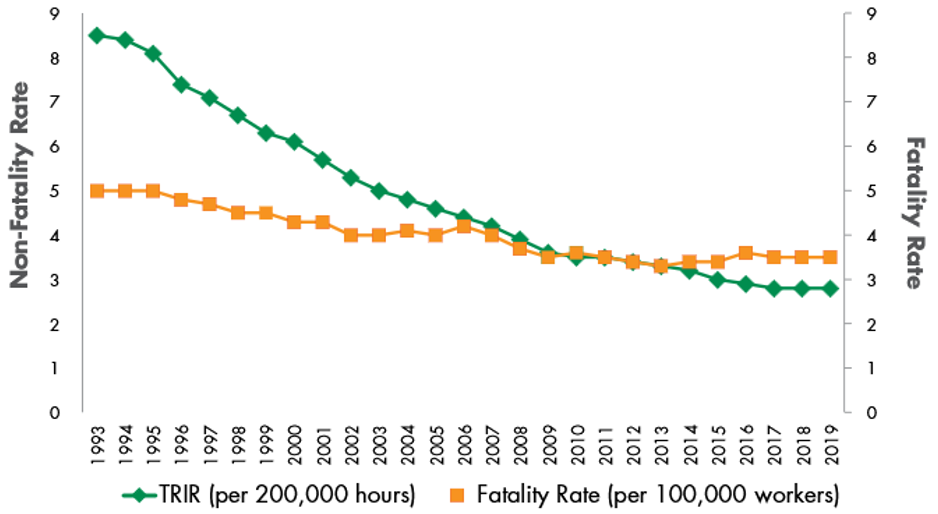

Figure 1: The total recordable incident rate (TRIR) and fatality rates in the industries in the past decades in the USA, DEKRA, North America. (Image credits: https://clocs.org.uk/wp-content/uploads/2024/09/dekra-twp-sif2-0.pdf)

A serious injury and fatality (SIF) event is the occurrence of an actual or potential incident that results in death or life-changing injury or illness. Life-changing events can cause permanent disability due to loss of organ function or body part or death in the absence of immediate care.

Near-miss events are considered to have SIF potential. Many industries use the Dekra definition of near-miss events, which describes it as a high-risk situation due to absence, ineffective implementation, or noncompliance with control measures, which can result in serious injury or fatality.

Accidents and events can be physical or chemical in nature. Since many hazardous chemicals are used in industries, they are one of the leading causes of SIFs.

Historically, the focus has been reducing total recordable injury rates (TRIR), and efforts have successfully brought down total injury numbers. However, this effort focus cannot control SIF events.

According to Dekra, SIF incidents occur rarely. They can be written off as an anomaly when they result from significant problems in a business’s design, implementation, and culture. Hence, workplace injuries have reduced over the decades, but SIF rates have not decreased much in the USA, as shown in Figure 1. Moreover, 25% of the recordable incidents have SIF potential.

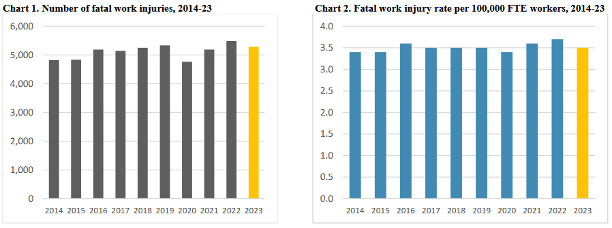

U.S. workplace injuries and illnesses were reduced from 10.9 to 2.7 daily incidents between 1972 to 2022. However, SIF rates are still high. The reduction in daily deaths was only 38 to 15 between 1972 and 2022. According to the U.S. Bureau of Labor Statistics, the rate of SIF continues to reduce, as shown in Figure 2, but there were 5,283 fatalities in workplaces in 2023.

Annually, in the European Union, there are 3700 workplace fatalities.

Figure 2: SIF rates in the U.S. between 2014-2023. (Image credits: https://www.bls.gov/news.release/pdf/cfoi.pdf)

Regulatory Requirements

Focusing only on SIF is necessary to bring their rate down. Hence, several countries now have regulations requiring immediate SIF event reporting.

In the U.S., since 2015, the Occupational Safety and Health Administration (OSHA) requires that every employer report all work-related SIF incidents as per the Recording and Reporting Occupational Injuries and Illnesses standard (29 CFR 1904.39).

- Work-related serious injuries and illnesses like hospitalization, amputations, or loss of an eye, etc., must be reported within 24 hours.

- Workplace fatalities must be reported within 8 hours.

Employers and safety managers can learn about OSHA reporting rules using the osha.gov/report resource.

Measures to Prevent SIF

Industries are moving away from relying only on the incident rate to evaluate their facility’s safety. The high SIF rates have led experts to conclude that focusing on control measures designed specifically for these accidents is necessary. Companies should make preventing SIF events one of their top priorities.

Dekra, the world’s largest organization of experts for testing, inspection, and certification, with a scope to make roads, workplaces, and homes safe, recommends industries use their “SIF Prevention Model.” The model suggests that safety managers:

- Find out the company’s SIF exposure profile.

- Educate all personnel in SIF hazards, exposure identification, controls, and prevention concepts.

- Develop SIF risk management plans.

These aims can be achieved by risk assessment, implementing solutions, and governance.

SIF exposure profile assessment: Safety managers must identify the types and frequencies of various SIF exposure risks in their facility and the organizational readiness to implement SIR prevention measures.

Implementing solutions to reduce SIF exposure: Once the risks are assessed, specific mitigation measures for a facility must be identified and implemented based on findings from the profile assessment. Measures can include interventions in risk management plans, incident investigation, governance, leadership development, employee engagement, and human performance reliability.

One of the main components is site-level exposure reduction teams, which are incorporated into the management.

Governance: Senior leadership in a business must understand and support SIF prevention measures to decrease injury and death numbers. Improved decision-making and governance are necessary for successful safety programs.

Preventing SIF is an ongoing process involving learning from mistakes and updating systems as required.

Most Effective SIF Preventive Measures

A 2022 review of preventive measures in the EU covered 100 studies, 120 interventions, and 417,693 companies/groups to find the best means to bring SIF rates down. These were the main findings of the study:

- Organization-level efforts: Efforts should be focused and directed at the entire organization and not individuals. A combination of methods organized by the institutions that provide working environments, tools, and machinery is essential. Focusing on workers’ role in mitigating risks should be the last option.

- Engineering solutions: The most effective interventions were engineering solutions, including elimination and substitution, that separated workers from the hazards. Effects improved when control measures did not involve worker “decision‐to‐”

- Multifaceted approach: Safety training programs are crucial to bringing SIF down, but they are more effective only when combined with other control measures.

- Government interventions: Regulations and enforcement are less effective but are helpful as they cover many organizations and workers.

A multifaceted approach involving the entire organization and engineering controls had the best results by avoiding risks at the source.

Tips to Reduce SF Rates

The National Safety Council introduced the “Work to Zero Initiative” in 2019 to reduce SIF rates. It shows that technology can help businesses make the workplace safer. Listed below are some of their suggestions.

Incorporate new metrics: Conventional after-the-fact metrics like injury and illness rates and lost-time incidents are insufficient. Greater attention to specific risks that increase the chance of SIFs must be included.

Change of attitude: Employers and decision-makers have a more significant role in eliminating SIF by introducing state-of-the-art technology and work protocols than worker operational competence. So, employers and management must take responsibility for making the necessary organizational changes.

Not setting safety targets: Some companies do not set SIF reduction targets to prevent hesitancy in incident reporting. Counting actual incidents as well as near-misses as SIF can improve safety standards.

Allow manual assessment: In facilities lacking digital solutions, safety managers and industrial hygienists can manually assess SIF experience and case studies to determine incident frequencies and causal factors. Near misses can be categorized on the chance of being a SIF incident on a scale of 1-10.

Software for choosing HOC: Organizations could use scenario modeling software to assess a situation and choose the optimal Hierarchy of Controls (HOC) option to reduce risk, such as the Environment Health and Safety Management solutions.

Automatic SIF identification: Some software can collect, analyze, and get insights from data to identify SIFs automatically. However, care should be taken to encourage reports by workers to gain a better understanding.

Use new technology: Employers should benefit from the latest tested technology to increase safety. They can use new, lighter personal protective equipment (PPE), portable gas sensors for confined spaces, etc.

Remote technologies: Remote and automatic tools, voice-activated machine control, and tasks by drones or robotics in high-risk environments can separate workers from hazards.

Education and training: Occupational training programs must include SIF incidents, causes, special measures, and feedback. This training should be given to owners, managers, and workers.

Collaborative safety initiatives: Employers can collaborate with industry associations, non-profit organizations, and government agencies to exchange knowledge for continuous improvements. Knowledge shared could be best practices, research findings, and resources on industrial hygiene safety and health.

Gas Analyzers for SIF Rate Reduction

One of the technologies that can reduce SIF is precision gas analyzers. Remote and fixed analyzers that operate 24 x7, even in high-risk areas without workers’ involvement, can provide information on the gas levels in industries and can sound alarms to allow for rapid and timely evacuation of personnel to prevent exposure to toxic gases or escape explosions, thereby reducing SIF incidents. Portable gas devices can be carried into confined spaces to give real-time information and warnings on hazardous gas levels so that personnel can take appropriate action.

Interscan provides fixed and portable gas analyzers for over 20 hazardous gases in several industries. It is a trusted firm whose analyzers have been used by NASA.

Find out more about Interscan Gas Analyzers to reduce SIF rates in your workplace.

Sources

ASSP. (2021, May 24). Three Keys to Preventing Serious Injuries and Fatalities. Retrieved from https://www.assp.org/news-and-articles/three-keys-to-preventing-serious-injuries-and-fatalities

Campbell Institute & National Safety Council (2020 Feb). Designing Strategy for Serious Injury and Fatality Prevention. Retrieved from https://www.thecampbellinstitute.org/wp-content/uploads/2020/02/Campbell-Institute_Designing-Strategy-for-Serious-Injury-and-Fatality-Prevention.pdf

DEKRA. (2021). DEKRA Serious Injury & Fatality (SIF) Prevention Services:

A Foundation for Sustainable SIF Exposure Control. Retrieved from https://clocs.org.uk/wp-content/uploads/2024/09/dekra-twp-sif2-0.pdf

Dyreborg, J., Lipscomb, H. J., Nielsen, K., Törner, M., Rasmussen, K., Frydendall, K. B., Bay, H., Gensby, U., Bengtsen, E., Guldenmund, F., & Kines, P. (2022). Safety interventions for the prevention of accidents at work: A systematic review. Campbell systematic reviews, 18(2), e1234. https://doi.org/10.1002/cl2.1234

European Commission. (n.d.). Industrial safety. Retrieved from https://environment.ec.europa.eu/topics/industrial-emissions-and-safety/industrial-accidents_en

Industrial for an Industrial Safety Culture-EU. (n.d.). Preventing serious, fatal and major technological accidents. Retrieved from https://www.icsi-eu.org/en/preventing-serious-fatal-major-accidents

News Release BLS. (2024, Dec 19). National census of fatal occupational injuries in 2023. Retrieved from https://www.bls.gov/news.release/pdf/cfoi.pdf

Onshore Safety Alliance. (n.d.). Serious Injuries and Fatalities (SIF). Retrieved from https://www.onshoresafetyalliance.org/resources/what-is-a-sif

OSHA. (n.d.). Severe Injury Reports. Retrieved from https://www.osha.gov/severeinjury