Ethylene Oxide (EtO) is a colorless, flammable gas that plays a pivotal role in the healthcare industry, primarily utilized for sterilization processes. The significance of this gas extends beyond its functionality in medical applications to a landscape dotted with health implications that industrial workers must recognize and mitigate.

Despite its effectiveness, Ethylene Oxide is highly reactive and exposes healthcare workers to considerable health risks, primarily through inhalation. Research shows that long-term exposure can lead not only to respiratory and skin irritations but also to severe conditions, including cancer and other health issues. Data indicate that workers in healthcare settings and contract sterilization facilities can experience EtO concentrations ranging from 0.0007 ppm to 10.1 ppm, often exceeding the Occupational Safety and Health Administration (OSHA) permissible exposure limit of 1 ppm. Such statistics highlight an urgent need for efficacious healthcare gas monitoring systems that can detect and respond to these hazardous exposures in real time.

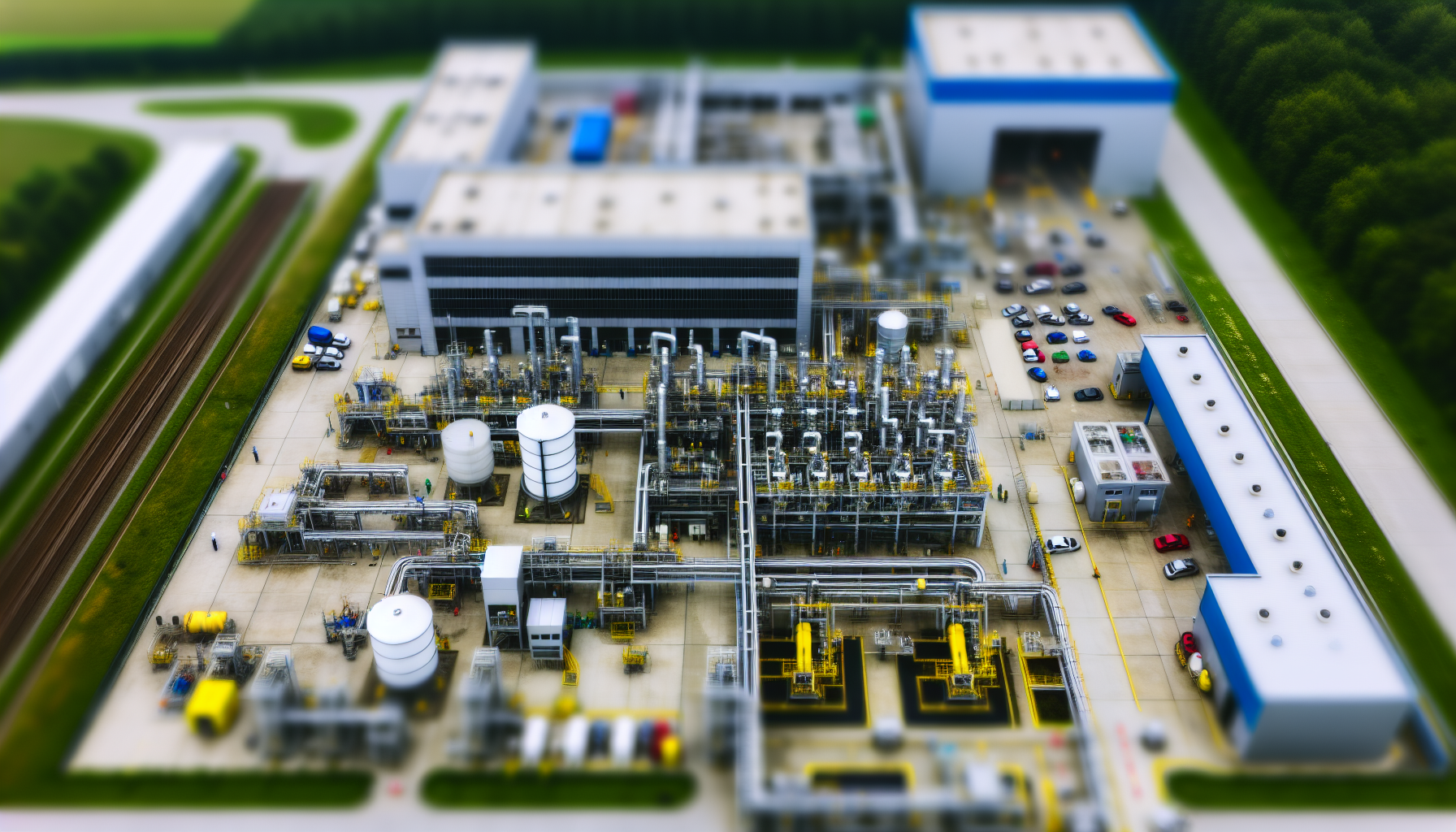

Facilities employing Ethylene Oxide often find themselves dealing with common sources of exposure. These include sterilization chambers and various cleaning processes that utilize the gas, which necessitate vigilant monitoring to protect personnel and patients alike.

Recognizing the Need for Effective Healthcare Gas Monitoring

In recent years, regulatory bodies have reinforced the need for robust health and safety standards that mandate Ethylene Oxide monitoring in healthcare environments. OSHA has set forth a permissible exposure limit of 1 ppm as an 8-hour time-weighted average (TWA)—but simply establishing regulations does not eliminate the risks associated with Ethylene Oxide. For compliance and, more importantly, the safety of staff and patients, facilities must prioritize effective monitoring systems.

Nevertheless, current monitoring challenges present significant obstacles. Traditional gas detection methods often lead to false alarms due to limitations in sensitivity and accuracy. These deficiencies can make timely intervention difficult and keep exposure levels at unsafe thresholds, jeopardizing the health of those within the facility.

The consequences of inadequate monitoring are dire. Insufficiently identified EtO concentrations risk not only the health of healthcare workers but can also diminish patient safety, lead to potential legal ramifications, and create non-compliance issues that prompt increased regulatory scrutiny. Thus, reliance on outdated monitoring methods must give way to innovative solutions.

Implementing Advanced Detection Solutions for Ethylene Oxide

To overcome the challenges presented by traditional monitoring methods, healthcare facilities must seek out advanced detection solutions for Ethylene Oxide. Recent advances in sensor technology, particularly the advent of electrochemical sensors, allow for continuous monitoring of EtO levels, enhancing both efficiency and response times. The importance of real-time monitoring systems cannot be overstated. By providing continuous data on Ethylene Oxide concentrations, these advanced technologies allow personnel to respond immediately—if levels exceed the regulatory limit of 1 ppm, alerts can trigger necessary interventions, safeguarding against harmful exposure. Moreover, integrating real-time data into safety protocols not only facilitates compliance with health regulations but also fosters a safety-first culture within the workplace.

However, selecting the appropriate monitoring equipment is essential for optimizing safety practices. Key features should include high sensitivity to detect Ethylene Oxide at trace levels, outstanding accuracy to ensure reliable data, and ease of integration with existing safety protocols. Interscan’s offerings encompass both fixed-point and portable detection solutions based on electrochemical sensors, letting users benefit from real-time readings and trace-level detection capabilities.

As we delve deeper into enhancing workplace safety through training and procedural refinement, the emphasis on comprehensive staff education regarding toxicity will become paramount. Training initiatives can significantly contribute to a safer work environment when personnel are equipped with knowledge about their work environment and the tools available to safeguard health.

With a pressing landscape that requires updated protocols and practices, the next sections of this article will explore the importance of establishing emergency procedures for Ethylene Oxide exposure incidents and promoting a culture deeply rooted in safety. The stakes are high, and commitment to effective gas monitoring cannot be understated. Stay tuned as we navigate the essential elements that bolster safety and compliance in the healthcare industry.

Enhancing Workplace Safety Through Training and Procedures

Establishing comprehensive training programs is critical to ensuring workplace safety in environments where Ethylene Oxide is used. Workers must be educated about the risks associated with Ethylene Oxide exposure and receive thorough instructions on using monitoring equipment effectively. Clear emergency procedures are equally vital. Medical facilities should develop and regularly update protocols for responding to Ethylene Oxide exposure incidents. These protocols should include evacuation plans, immediate reporting systems, and first-aid measures to protect workers in the event of an incident. Furthermore, fostering a culture where safety practices are prioritized by all staff members will enhance adherence to these emergency procedures, ultimately leading to a more vigilant workplace atmosphere.

Addressing Industry Trends and Future Considerations

The healthcare landscape is shifting, which will undoubtedly impact the usage of Ethylene Oxide for sterilization purposes. As the industry evolves, facilities will increasingly explore alternative sterilization methods that minimize reliance on Ethylene Oxide.

Additionally, regulatory bodies are anticipated to tighten existing exposure limits and enhance reporting requirements. This anticipated shift underscores the need for facilities to remain vigilant and adaptable in their monitoring practices. Moreover, emerging innovations in gas detection technologies, such as advanced sensor systems that achieve part-per-trillion precision, promise to redefine how Ethylene Oxide exposure is monitored. These advancements will enable quicker detection and response times, significantly improving workplace safety.

Latest Ethylene Oxide Monitoring Solutions

Interscan stands at the forefront of gas detection technology, offering solutions tailored to meet the unique challenges posed by Ethylene Oxide in healthcare settings. By providing real-time readings and trace-level detection, our electrochemical sensors enable healthcare professionals to monitor Ethylene Oxide levels effectively, ensuring compliance with regulatory standards while prioritizing the safety of staff and patients. With Interscan’s advanced monitoring systems, healthcare facilities can not only enhance their gas detection methods but also foster a culture of safety that protects everyone involved in patient care.