Nitrogen dioxide (NO2) presents significant health and safety risks across various industrial environments. Recognizing these hazards is crucial for industry professionals aiming to protect their workforce and ensure compliance with safety regulations. This toxic gas is not only reactive but also accumulates in high concentrations, especially in settings with limited ventilation. Research indicates that prolonged exposure to NO2 can lead to severe respiratory issues, including decreased lung function and increased susceptibility to infections. Workers exposed to NO2 face a heightened risk of developing chronic respiratory diseases.

Understanding these implications is essential for implementing effective safety protocols. Industrial workers and managers alike must remain aware of the potential dangers posed by nitrogen dioxide to foster a safe working atmosphere. For more detailed information, visiting the Interscans Nitrogen Dioxide info page can be beneficial.

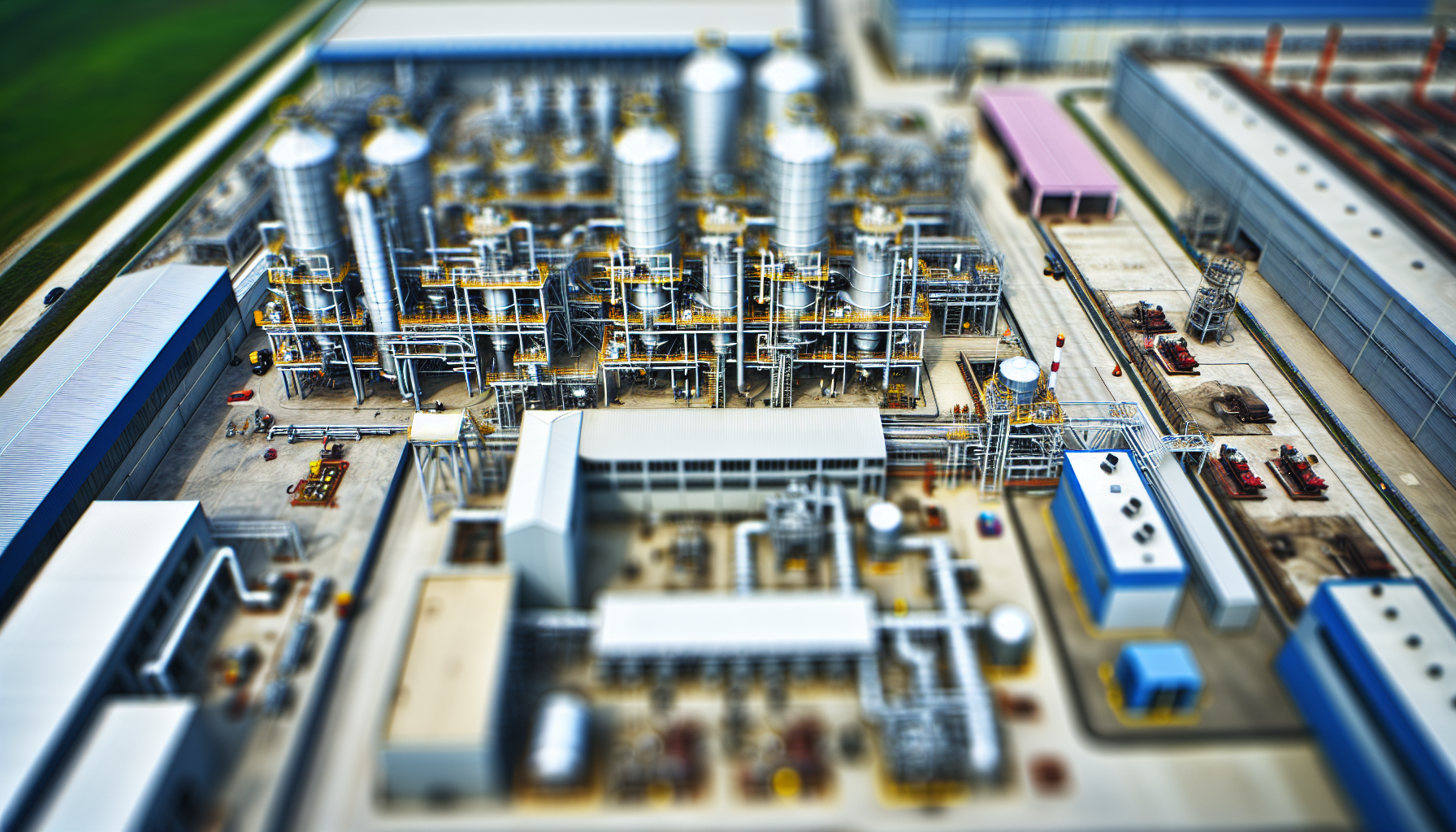

Identifying the Need for Effective Gas Reaction Monitoring Techniques

Given NO2’s hazardous nature, effective monitoring of its gas reactions has become a vital concern in industrial operations. The ability to detect nitrogen dioxide concentrations accurately and in real-time is imperative. Industry professionals frequently encounter challenges when existing systems fall short in delivering timely data, sometimes displaying results with a lag of several hours, which could have catastrophic consequences in a high-risk environment.

As the need for improved detection methods intensifies, the gap in current monitoring technologies becomes more apparent. A thorough understanding of emission pathways and real-time concentration changes is critical for prevention and response efforts.

Implementing Advanced Gas Detection Technology

To surmount the challenges associated with monitoring nitrogen dioxide, industries must adopt advanced gas detection technologies that yield precise and dependable results. Equipping teams with state-of-the-art tools, such as GasD8000 Portable Gas Detector, is no longer just a recommendation but a necessity to secure workplace safety.

Research showcases impressive developments in gas detection. This advancement significantly elevates safety protocols in industrial applications, enabling swift decision-making and response to hazardous conditions. With these technologies, professionals can maintain vigilant oversight of nitrogen dioxide levels, ensuring that safety measures are both proactive and reactive.

Recognizing the Complex Chemistry of Nitrogen Dioxide

The chemistry surrounding nitrogen dioxide is intricate and multifaceted, posing inherent challenges in managing its presence in industrial processes. Crucial reactions involving NO2 can occur under various conditions, complicating detection and control efforts. For instance, NO2 can react with volatile organic compounds (VOCs) in the presence of sunlight, forming secondary pollutants that can significantly impact air quality. These reactions’ rates are notably influenced by environmental factors such as temperature and humidity, making emission control strategies more complex and multifaceted.

Industry professionals must grasp these chemical interactions to develop effective strategies for managing nitrogen dioxide emissions and preventing dangerous situations. A solid foundation in NO2 chemistry is not merely advantageous; it is essential for safeguarding health and ensuring compliance with environmental regulations.

Enhancing Knowledge of Nitrogen Dioxide Chemistry

Educating and training personnel on nitrogen dioxide chemistry is paramount in implementing effective safety measures and responding to the associated risks. A well-informed workforce is better positioned to recognize the potential dangers and react appropriately to changes in gas concentrations.

Organizations have begun to leverage innovative training methodologies, such as simulation-based learning, allowing employees to better understand nitrogen dioxide’s behavior and interactions. Such programs can yield notable increases in comprehension regarding NO2’s chemical properties and safety protocols.

Such proactive training not only enhances knowledge but also cultivates a culture of safety within the organization.

Addressing Regulatory Compliance and Safety Standards

Non-compliance with safety regulations surrounding nitrogen dioxide can have dire repercussions for businesses. Therefore, staying abreast of local and federal regulations is crucial for industry professionals. Regulatory bodies like the Environmental Protection Agency (EPA) have instituted stringent guidelines concerning nitrogen dioxide emissions. As these and other states begin to adopt even stricter measures, the urgency for compliance increases. For more comprehensive solutions, explore the Interscans Product catalog.

Understanding specific regulations applicable to each facility empowers companies to maintain operational safety and avoid potential legal repercussions.

Utilizing Comprehensive Gas Detection Systems for Compliance

By integrating comprehensive gas detection systems specifically designed to monitor nitrogen dioxide, companies can more effectively adhere to regulatory compliance while fostering a safer work environment. These systems facilitate timely detection and response to elevated NO2 levels, which is crucial for preventing adverse outcomes in industrial settings.

Implementing such monitoring systems can enhance overall safety and contribute to a compliant and transparent operational framework.

Addressing All These Challenges with Interscan Solutions

Interscan offers advanced gas detection solutions tailored to monitor nitrogen dioxide effectively in diverse industrial settings. With cutting-edge technology that champions reliable gas reaction monitoring and real-time analytics, Interscan empowers industry professionals to mitigate risks associated with nitrogen dioxide exposure. As we will explore further in the second half of this article, these state-of-the-art systems are not just about detection; they provide critical support in ensuring workplace safety and regulatory compliance. Stay tuned as we delve deeper into the advanced functionalities and operational benefits of Interscan’s solutions.

Recognizing the Necessity for Training in Gas Detection Technologies

With the critical importance of understanding nitrogen dioxide chemistry, there is a concurrent necessity for comprehensive training on gas detection technologies. Industry professionals must be equipped not just with awareness about the hazards of NO2 but also with knowledge on operating detection equipment efficiently. Effective training programs, which emphasize hands-on experience with equipment and safety protocols, can greatly enhance the capability of employees to respond to unsafe nitrogen dioxide levels.

Moreover, the role of simulation-based training has been shown to be particularly effective, fostering an increase in understanding of nitrogen dioxide properties among participants. In this way, professionals can feel empowered to operate state-of-the-art gas detectors confidently, ensuring that they are not only compliant with safety regulations but also actively contributing to a safe working environment.

Implementing Interscan’s Cutting-Edge Technology

Interscan stands at the forefront of gas detection solutions, offering both fixed-point and portable detection systems based on electrochemical sensors. These devices provide real-time readings and trace-level detection capabilities, essential for monitoring nitrogen dioxide in various industrial scenarios. With their quick-exchange sensor system known as the ‘Interchange Sensor,’ Interscan enables easy maintenance and adjustment, ensuring that businesses can minimize downtime and maintain safety standards. This innovative approach allows teams to swiftly react to any changes in gas concentrations, thereby significantly reducing potential health risks.

Furthermore, real-time data from these systems aids in the understanding of gas behavior under different operational conditions, facilitating better emission control strategies in compliance with regulatory standards. Systems that provide immediate monitoring and alerts can greatly reduce incidences of dangerous exposure, reinforcing the importance of integrating advanced technology into safety protocols.

Incorporating advanced gas detection systems, such as those provided by Interscan, along with comprehensive training programs on nitrogen dioxide chemistry, is imperative for ensuring safety in industrial workplaces. By prioritizing the implementation of reliable monitoring technology and investing in the continuous education of staff, organizations can effectively mitigate the risks associated with nitrogen dioxide exposure. Through proactive measures and adherence to regulatory standards, industrial professionals can create a safer environment, safeguarding the health and well-being of their workforce while ensuring compliance with evolving regulations. For further assistance, Request a quote from Interscan.